A range of bandpass filters from REO (Boulder, CO) operate in the visible, near-infrared and mid-infrared spectral ranges for spectrometry and temperature sensing. Nominal bandwidth is 1% (FWHM) of the center wavelength, with a peak transmission of 60% and a linearity of ±0.5%. Available in optical glass, fused silica and substrate materials, sizes range from 3 × 1.5 mm to 150 × 65 mm. Short-wave pass and long-wave pass edge filters are also available.

-----

PRESS RELEASE

FOR IMMEDIATE RELEASE

12/15/10

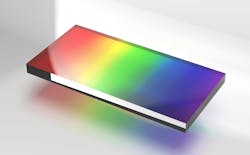

Cost Effective, Linearly Variable Bandpass and Edge Filters

REO, a leading manufacturer of high volume precision optical solutions, has launched a new range of linearly variable bandpass and edge filters useful for applications in spectrometry and temperature sensing. In these variable response coatings, the center wavelength of operation changes with position in a linear manner over the surface of the part. In the past, high manufacturing costs for this class of filters has limited their use to a few specialized applications. But now, REO has developed a unique, proprietary, volume scalable technology which enables cost effective production of linearly variable filters over a wide range of sizes.

REO currently offers bandpass filters for operation in the visible (380 nm – 760 nm), near infrared (600 nm – 1100 nm) and mid-infrared (1.3 µm – 2.6 µm) spectral ranges. Nominal bandwidth is 1% (FWHM) of the center wavelength, with a peak transmission of 60% and a linearity of ±0.5%. These can be delivered on a wide array of optical glass, fused silica, as well as other substrate materials in the 3 mm x 1.5 mm (L x W) to 150 mm x 65 mm size range. Short wave pass and long wave pass edge filters are also available over the same spectral range and substrate sizes. All these filters are fabricated using ion beam sputtering (IBS) technology in order to minimize scatter and absorption, and to make coating response totally insensitive to changes in temperature and humidity.

In addition to the product detailed here, REO can produce a wide range of other linearly variable filter configurations on a custom basis.

About REO

REO produces high precision thin film coatings, optics and opto-mechanical assemblies for the ultraviolet, visible and infrared. Located in Boulder, CO, the company primarily services medium to high volume OEMs including manufacturers of defense and aerospace systems, laser systems, semiconductor tools, medical systems, life sciences instrumentation and telecom equipment. REO is a privately held company. For more information, contact Mark Damery, Vice President and General Manager of Worldwide Sales, at +1-720-562-3213, e-mail [email protected], www.reoinc.com, or Susan Anway, Vice President of Finance and Chief Financial Officer at +1-720-562-3206, e-mail [email protected].