On many fronts, technical advances arise from shrinking size—nano-this and micro-that. That's what micro-optics brings to imaging. "To me, it means lenses and prisms on the order of submillimeters or hundreds of microns," says Ethan Schonbrun, an expert in optofluidic cytometry at Harvard University (Cambridge, MA). "The small size is so powerful because that lets elements be parallelized in ways that are not possible for bulk optics." Along with Schonbrun, experts from Fisba Optik (Gallen, Switzerland), OptoSigma (Santa Ana, CA), and Bern Optics (Westfield, MA) explained this technology and how it expands opportunities in life science research.

Although size plays a key role in micro-optics, the technology delivers more than miniscule optical components. "To some extent, micro-optics means the ability to implement a custom optical system for a specific task," Schonbrun explains. "Often, off-the-shelf optics can be used for many different applications."

Micro-optics, on the other hand, tend to be designed in systems—even homemade ones—that perform very specific tasks. As Schonbrun says, "Micro-optics can be designed in much more custom ways to measure a very specific event or quantify a cell type in a particular way."

Going inside

The custom aspect of micro-optics also impacts where they get used. "Recently, large advances in the fabrication of micro-optics allow them to be integrated in a device, whereas bulk optics are usually external," Schonbrun says.

As an example, an array of micro-optics could go in a chip-based device. "This allows cells to be manipulated with a resolution that is similar to the size of cells themselves," says Schonbrun.

At Harvard, Schonbrun and his colleagues use micro-optics in a chip system that performs cytometry. "It's for quantifying cell properties, like cell volume and cell scattering cross-section," Schonbrun explains. This microfluidic chip parades cells by micro-optics. The cells can be treated with, for example, drugs, and the micro-optics can determine the geometry of the cells, which can indicate the health of the cell.The cells can also be labeled with fluorescent tags to detect specific features, such as a protein. "These labels can emit a few colors," says Schonbrun, "often spaced by tens of nanometers in wavelength, and that is easily detected by lots of miniature spectrometers, which can be created with micro-optics."

Designing and manufacturing such a specialized micro-optics system, though, demands extensive experience. For instance, Schonbrun and his team manufacture their own chips. He says, "The fabrication becomes a challenge."

Order-up options

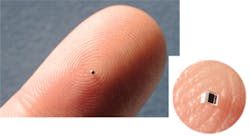

Luckily, a life scientist interested in using micro-optics does not need to become a chip designer and fabricator because researchers can purchase many micro-optics components. The items that fall into the micro-optics category, however, depend in part on opinion. For example, when asked to define micro-optics, Urs Schneider, optical solutions account manager at Fisba Optik, says, "The optical component has a diameter of less than 1 mm for round optics." He adds, "For a FAC-fast axis collimation-lens, the thickness is relevant. It should be also below 1 mm."Other companies draw the line in a different spot. For example, Andrew Clawson, product manager for optics and optical coatings at OptoSigma, says, "For us, it's basically below about a 5 mm diameter." He adds, "We only get down to about 1 mm." Bernd Gottschalk, president of Bern Optics, notes that his company specializes in submillimeter optics, a term that confuses some. "Submillimeter optics relates to the actual dimension of the parts rather than the wavelengths" of light, he says. "We use it to describe our conventionally ground and polished components that measure below one millimeter, and to differentiate this manufacturing process from photolithography or replication."

In some cases, it's not the size of the components alone, but the systems themselves that makes the difference. As Schneider says, "At Fisba, optical microsystems are defined with the volume, usually below 1.5 cubic centimeters."Whether a scientist wants parts or a complete system, Schneider sees several growing applications of micro-optics in the life sciences. He points out portable devices for analytical tests. He adds, "Minimal invasive surgeries shorten the recovery of patients and reduces healthcare costs." Overall, he mentions that "miniaturization is a global trend."

As an example of making things smaller, Fisba developed a micro-camera with four lenses. "The lens diameter is below 1 mm," Schneider says. The small size could be useful in life science applications where space is at a premium.

In general, Fisba supplies components or systems to device manufacturers. In some cases, Schneider says, "Scientists buy one or two samples for basic tests and write their publications." He adds, "The latest example was a laser tweezers application with one of our laser modules. The goal was trapping beads in a highly parallel manner within a micro fluid."

Bern's Gottschalk explains that submillimeter optics are used in a wide variety of rigid and flexible medical endoscopes to provide magnification and high-resolution imaging of internal body parts for diagnosis and/or treatment. They have also been adapted for use in endomicroscopy, a technique for achieving histology-like images in real time.

Bending in the brain

Some biological situations really create a tight squeeze for experiments. Working in the brain can be one of the tightest and most delicate situations. To help with that, OptoSigma developed a right-angle, micro-optics prism. "These are typically used for in vivo applications," Clawson says. "Scientists have developed a two-photon imaging technique by inserting these in mouse brains." To reduce photodamage, this technique uses two photons, each of half the energy needed to excite the target label. As Clawson says, "They use these prisms to send the laser illumination through and then pick up the fluorescence emitted by the tissue."

Despite the small size of micro-optics, they keep getting features of large optical components. For example, Clawson says that one trend in making them is the ability to add coatings to millimeter-size optics.

Although most life scientists will not develop micro-optics systems like Schonbrun and his colleagues do at Harvard, everyone can put these devices to some use. Clawson says, "Life scientists can contact me or visit our website. We can help point people in the right direction."

That direction-as in all optical applications-depends on the problem at hand. Simply knowing that micro-optics exist, though, should give many biologists new ideas for how they might use them. Even off-the-shelf components can be hooked together in ways that allow new kinds of imaging and analysis. If scientists can use these optical devices to look inside the brain, just imagine the other processes in nature that could be explored.