Numbers show that the thermal camera market remains quite promising, with Yole Intelligence anticipating 6% compounded annual growth. And as interesting applications continue to surface, it is no surprise there has been an explosion in growth in the longwave imaging market. As a result, the willingness to pay for the innovations and the actual costs have collided. The midwave-infrared (MWIR), however, is a different story, with most cameras still cryogenically cooled—meaning the typical price tag sits around $100,000 per unit.

“There are many advantages in the MWIR. And some of them come because it is cryogenically cooled, such as lower noise and better sensitivity,” says LightPath Technologies CEO Sam Rubin. “In this space, you are looking at very high temperature events, which translate into very specific for us. It also gives us some spectral activity from the photonics point of view that happens in the MWIR, mainly around spectroscopy and gas detection.”

When looking at the IR imaging market with the shortwave-infrared (SWIR), MWIR, and longwave-infrared (LWIR), LightPath Technologies (Orlando, FL) knew there was something in between, some areas that are not covered well enough—areas that are important and interesting in spectroscopy, for example. IR technology has come a long way for cameras in the past decade. And the advancement in uncooled microbolometers has really enabled LWIR imaging to enter new arenas where it was just too expensive, including firefighting, hunting, security, and defense. These are all areas where thermal imaging without uncooled devices was not feasible.

LightPath has since released an uncooled camera, known as the Mantis, covering from 2 to 14 µm—it is truly multispectral, covering the MWIR, all of LWIR, and even a little bit of SWIR at 1 mW. Being an uncooled device, Mantis does not have the sensitivity of the cryogenically cooled MWIR camera, but it addresses use cases where the goal is to identify images spectrally existing in the MWIR, but where the same level of sensitivity is unnecessary.

What makes the Mantis camera unique is its optical system’s ability to maintain focus over the entire wavelength range. “It’s truly a chromatic of 2 to 14 µm possible through material advances possessing different dispersion curves and behaviors,” Rubin says. “As such, we are able to make a lens assembly that does not require refocusing when you’re looking at different wavelengths.”

Understanding the applications

Defense represents a big area of opportunity for the Mantis camera. After all, when shooting a gun or a cannon, there’s a muzzle flash that is entirely in the MWIR to the gray body kind of behavior. Mantis enables drones or even stationary cameras to accurately look for these flashes.

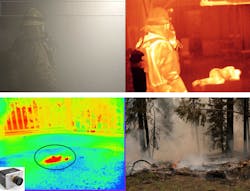

Firefighting is also an attractive application. LWIR cameras are used extensively today to see through smoke and differentiate between the environment and a person in the center of the fire. Unfortunately, they cannot image smoldering material, which is why firefighters often remain at a scene for hours after the fire is visually extinguished to make sure the fire doesn’t restart (see Fig. 1).

Smoldering is a very concentrated, high-temperature event; therefore, LWIR cameras cannot really distinguish between smoldering and just general heat left behind. “If you look at an event with a LWIR camera, you see a regular heat signature that is hard to differentiate,” says Rubin (see Fig. 2). “We’re extremely excited about the prospect of enhancing the existing market of thermal cameras for firefighters to improve detection.”While both applications represent imaging advances within the uncooled realm, LightPath hasn’t fully explored many of the potential applications, including gas sensing, chemical analysis, agriculture monitoring, and material fatigue.

How does it work?

What LightPath has developed is a lens system that maintains the same focus and performance simultaneously in both the MWIR and LWIR with two distinct advantages. First, it can see through the glass where it is possible to not only see a blob of heat, but individual heat elements. “This means you can inspect to see how heat is being generated and distributed. Or where there might be a failure coming up if one of the elements is not heating as well as others,” says Rubin.

Mantis provides all the advantages of regular LWIR uncooled cameras, but also works in the MWIR, so atmospheric turbulences and atmospheric aberrations are significantly lower. Even with standard thermal imaging, you can simply see further away the longer distance because there are less disturbances in the atmosphere.

“Our ability to design and deliver an optical lens system that is truly multispectral with the same focus point, the same performance on both wavebands, or across a whole range is a big deal,” Rubin says. “Otherwise, what you would have to do is use two filters, switching back and forth between the two.”

Secondly, LightPath developed a unique calibration technology allowing calibration operation within the MWIR. “The calibration of thermal cameras has always been done using different blackbodies at different temperatures in the LWIR,” he says. “We had to come up with a unique approach that comes from working very closely with open plenary manufacturers and having a very good understanding of the mechanisms of the focal plane. We’ve revamped those to the focal-plane arrays that cover multiple wave bands that just continued to exist for either/or situations. We found a way to get them to work for both simultaneously.”