CARL JACKSON

For the past 75 years, the vacuum-tube-based photomultiplier tube (PMT) has served as the standard by which all low-light-level optical detectors are measured. Low-light sensing and the applications that have evolved from it would simply not exist without the technology behind the ubiquitous vacuum tube. In fact, many other items that are taken for granted today were made possible by the invention of the vacuum tube—the light bulb, the cathode-ray tube, the first diode, and the first computers all were made possible through the existence of the ability to evacuate a glass bulb and interact in that environment with an electric field. In each of these cases, semiconductors have either replaced or are making serious inroads to displacing their vacuum-tube equivalents.

The same migration from vacuum tubes is also occurring in the area of optical detection, as the PMT is facing competition from a silicon-based alternative known as the silicon photomultiplier (SPM). The replacement of the PMT with a more-robust and higher-performance SPM will allow the creation of more-sensitive, smaller, lower-power, and better-performing optical-detection equipment.

The silicon photomultiplier

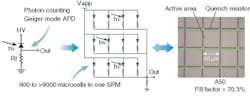

The SPM is a novel high-gain low-light sensor created by exploiting the single-photon-counting ability of the silicon Geiger-mode avalanche photodiode as fabricated in large parallel arrays from approximately 1000 to 9000 pixels (or microcells) in size. Each of the microcells in an SPM contains a single-photon-counting Geiger-mode avalanche photodiode and a quenching resistor (see Fig. 1).

The microcell contains a p-n diode with a specially designed amplification region generated between the anode and cathode that allows the low noise amplification of single photons into easily measurable output responses of approximately one million electrons per photon. Careful fabrication processes allow the diode to be biased above the breakdown voltage with no current flow until a photon initiates avalanche breakdown and a large current flow. By connecting the diode in series with a resistor, it is possible to create a reciprocating circuit in which single photons incident on the diode are amplified, then quenched by the voltage drop across the series resistor, and the diode recharged to its previous voltage above breakdown. This breakdown, quench, and reset cycle makes photon counting with silicon diodes possible and allows for highly accurate measurement of the quantity and arrival time of photons on the detector (see “Silicon photon-counting detectors enable next-generation imaging”).

The output of each microcell is connected in parallel with the outputs of the other microcells in the array. The output of an SPM is therefore the charge from each single-photon event incident on the individual microcells. This allows the SPM to have a quasi-analog output in response to the number of photons that are incident on the active area. Because of the high uniformity of the microcells, an exciting feature of the SPM is that it is possible to discriminate the number of photons incident on the detector as discrete levels on the output node. The ability to measure the single-photoelectron spectrum is a feature of the SPM that is not possible with PMT detectors, which have much more variability in the output response. What is truly novel in the SPM is that the high internal gain of the single microcells simplifies the external circuitry and the requirements on external amplification. This allows the fast (subnanosecond) timing response of the photon-counting microcell to be preserved.

There are several parameters that are important in assessing the performance of an SPM in comparison to a PMT. The most important of these are photon-detection efficiency, dynamic range, and signal-to-noise ratio (SNR).

Photon-detection efficiency

Because an SPM is made up of many individual photon-counting microcells, there is a trade-off between the dynamic range and the fill factor, and thus the photon-detection efficiency (PDE). Simply put, the more microcells packed into an SPM array, the higher the dynamic range, as there are more active microcells. However, because a quenching resistor is required for each microcell, there are limitations to the filling factor that can be achieved. The quenching resistor for each microcell takes up a small but significant fraction of space in the microcell and therefore reduces the overall photon-detection efficiency of the SPM array. The PDE is therefore a fundamental parameter of the SPM detector. The PDE represents the efficiency of the SPM at converting optical signals to a measurable electrical response. In an SPM, the PDE is equal to the quantum efficiency (QE) of the individual microcell (which approaches 50%) multiplied by the fill factor, or the ratio of active to nonactive silicon areas (see Fig. 1).

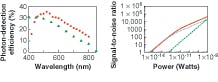

Typical PDE for 50 μm SPM detectors can be compared with those for a high-performance PMT typically used in life-sciences imaging (see Fig. 2). The SPM has a higher PDE in most of the visible spectrum; there is room in the silicon SPM structure to further optimize for blue and red wavelengths. Different active areas yield different fill factors and numbers of active microcells. A 20 μm circular microcell structure will allow an approximately 18% fill factor with 640 individual microcells, while a more-aggressive 20‑μm-square structure allows a fill factor of about 34% and 1144 microcells in a 1 × 1 mm SPM array. Moving to a 50 μm internal diameter for a microcell allows a fill factor of greater than 70% to be achieved with 302 individual microcells in a 1 × 1 mm SPM. In a 3 × 3 mm SPM, the number of cells increases with the area from 4496 for a 20 μm “standard” structure to 8640 for a 20 μm “aggressive” structure; 1930 microcells for a 50 μm aggressive structure are achievable in the larger SPM array size.Dynamic range

Considerations for the dynamic range depend on whether the optical signal is pulsed or continuous-wave. In a pulsed measurement, the dynamic range is a pure function of the number of microcells that are in the array. For applications such as nuclear medicine, high-energy physics, and radiation detection, the SPM is typically coupled with a scintillator that converts the high-energy signal pulses to visible photons. For these applications, the dynamic range of the SPM must be optimized to allow enough microcells to be available in the array to detect the signal with adequate resolution. It is possible to trade off dynamic range and PDE to produce a detector optimal for each application. A subnanosecond timing response, combined with robustness, magnetic-field immunity, and high PDE make the SPM well-suited for these applications in comparison to PMTs.

In a continuous-wave application, the signal is typically read out over longer time periods ranging from a microsecond to seconds. Therefore the dynamic range is a function of the number of microcells that can be activated in the time period, allowing for the minimal dead time (typically less than 50 to 100 ns) for the microcell to recover from each photon event. For the most-aggressive 20 μm structures (with 8640 microcells), this represents dynamic ranges of up to 1.72 × 1011 photons per second with a 17% PDE, corresponding to light levels up to 360 nW.

Signal-to-noise ratio

Signal-to-noise ratios have been calculated for the SPM detector in continuous-wave mode, as well as for a standard p-i-n photodiode and a PMT (see Fig. 2). The analysis assumes a current high-performance PMT, the current SensL SPM detector performance, and a high-quality p‑i-n photodiode connected to a low-noise JFET (junction-gate field-effect-transistor) amplifier.1 Because of the intrinsic low noise amplification of the SPM detector (which has a low excess-noise factor), the SPM has a much higher SNR above 5 × 10-13 W (for a wavelength of 550 nm) than is possible with standard PMT detectors and p-i-n photodiodes. Below 5 × 10-13 W, the SPM has a slightly reduced SNR compared to a PMT; this is a function of the dark current inherent to the SPM detector. This dark current is being reduced through process improvements and, as the detector fabrication matures, will allow the SPM to fully replace PMT detectors in applications such as cell imaging, biomedical detection, nuclear medicine, high-energy physics, and radiation detection.

REFERENCE

1. Photomultiplier Tubes-Principles and Applications, Photonis, Brive, France (September 2002).

Carl Jackson is chief technical officer of SensL, Lee House, Riverview Business Park, Blackrock, Co. Cork, Ireland; e-mail: [email protected]; www.sensl.com.