Shanghai Optics offers custom optical solution services including Design for Manufacturing (DFM). We are proud of our long history of offering custom optical solutions for helping customers improve product performance and reduce manufacturing cost. Below is one example of a lens system we helped to reduce the optical size and lower the manufacturing cost for meeting the customers’ application requirements.

Reducing optical size and weight are very important for medical devices applications. A medical headset supplier needed a precision lens system with right-angle prism for bending the light and two aspheric lenses for focusing light. Our engineers did not use the proposed traditional glass material and complex mounting method for the design but came up with an optimized solution of shortening the optical length to meet customer strict size/length requirement and eliminating the reflection coating requirement to lower the manufacturing cost.

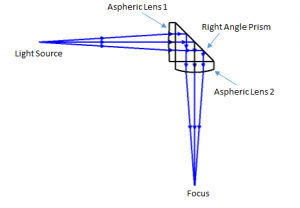

Figure 1 shows the lens system configuration.

• High refractive index material is used for the Right-Angle Prism to achieve total reflection (TIR) at a small angle of incidence. There is no need to have additional reflection coating on the prism surface for reflecting light, so manufacturing cost is reduced.

• Plano-convex aspheric lenses are cemented to the prism surfaces for eliminating the air gap between aspherical lens and prism. The optical system length is shortened, therefore the device weight is reduced.

Figure 1: Lens System Configuration

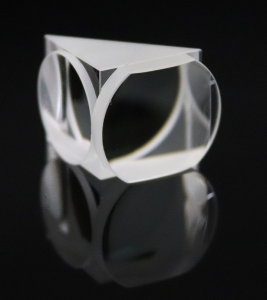

Figure 2 shows the cemented prism and lenses. The two plano-convex aspheric lenses are precisely aligned and cemented to the prism surfaces.

Two plano-convex aspheric lenses bonded to a right-angle prism

Contact us if we can help you with design for manufacturing (DFM) in your optical device or component. Custom optical design is our specialty, and our unique knowledge of manufacturing enables us to optimize your design for both performance and cost.