Key Takeaways

- The project uses microlens arrays on flexible substrates to control light precisely, benefiting UV, VIS, and NIR video imaging cameras with broad wavelength coverage.

- The project focuses on microlens arrays for video imaging cameras, which arrange multiple lenses on a substrate to enable precise light control in applications such as lighting, imaging, and photonics.

- Avantier excels in manufacturing, emphasizing cost-effectiveness and precision using aluminum for mounting plates, offering sets of twenty lenses with high-precision machining and surface treatments for durability.

Introduction

Lens arrays consist of multiple individual lens cells arranged directly on a supporting substrate, in either a one-dimensional or two-dimensional configuration. The supporting substrate materials can include glass, polymers, and metals. The primary objective of utilizing a lens array is often to manipulate light beams in a specific manner to cater to various purposes in different fields such as lighting, imaging, and photonics.

This innovative design allows lens arrays to play a crucial role in optical systems, achieving precise control of light by strategically arranging lens units. The applications of lens arrays are diverse, ranging from improving the efficiency of lighting systems to optimizing the performance of imaging devices. The application of lens arrayseven play a pivotal role in photonics research.

The supporting substrate of lens arrays is carefully chosen, providing flexibility for configuration based on the specific requirements of the application. Whether used to enhance beam focus or to disperse light for specific effects, lens arrays showcase versatility and adaptability in the field of optics.

Microlens Arrays Project Overview

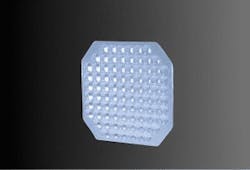

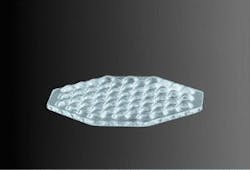

Microlens Arrays Specification

- Number of Lenses : 11 X 11

- Lens pitch number: 3000um

- Size: width: 7 mm; height 8 mm

This initiative is predominantly crafted for UV, VIS, and NIR video imaging cameras, which encompass an extensive wavelength spectrum spanning from ultraviolet to visible light and extending into near-infrared. It finds applicability across a multitude of potential fields. With its unparalleled spectral and spatial resolution and exceptional operational speed, this foundational high-spectral light field technology opens avenues for robust technological advancements, effortlessly accommodating the diverse requirements of our clientele.

We encouraged the client to articulate specific solution needs, whether it involved tweaking wavelength configurations or achieving optimal resolution. This enabled our technology to adapt seamlessly to these requirements. Additionally, with ongoing advancements in the sensor market, it is now feasible to adjust the wavelength range to cover every conceivable category including UV, VIS, and NIR.

This adaptability empowers our initiative to drive innovation across various application domains, continually evolving in response to shifting customer needs and technological advancements.

Custom Microlens Arrays

Avantier showcases a commitment to innovation and precision in optical technology in microlens arrays. The versatility of lens arrays, strategically arranged on carefully selected substrates, caters to diverse applications in lighting, imaging, and photons. The microlens array project, specifically designed for UV, VIS, and NIR video imaging, underscores Avantier’s dedication to meeting customer needs with adaptability and cutting-edge technology. By consistently delivering stellar performance and flexibility, we ensure our product remains at the forefront of customer satisfaction.

The use of aluminum mounting plates, coupled with advanced surface treatments, ensures high precision and durability, setting Avantier apart in the field. Continuous improvement in manufacturing makes Avantier a reliable choice for exceeding expectations in optical solutions.