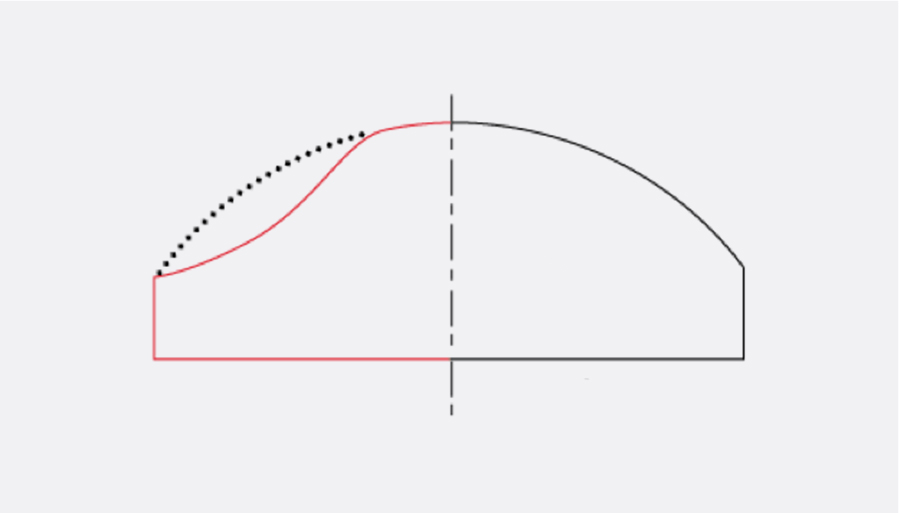

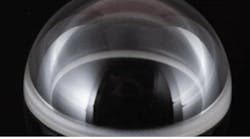

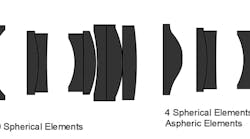

Aspheric lenses have at least one surface defined by an aspheric equation that has a fluctuating local radius across the diameter of the part. As a result, this creates an optical lens with a non-constant radius around the sphere.

LaCroix Manufacturing Engineers will analyze your print and aspheric lens design. They will match the sag table provided with the print to verify the correct custom aspheric lens is being manufactured. When sending a sag table and aspheric terms, do not truncate the vertex radius, conic constant, or any of the aspheric terms as we will not be able to match and verify your aspheric sag table.

Aspheric Lenses v. Spherical Lenses

Measuring Aspheres in a 3-D WorldWhite Paper Manufacturing Considerations forTolerancing Aspheres White Paper

The manufacturing process of aspheric lenses begins by designing a near-net shape optical glass blank. To generate a best-fit sphere into the aspheric lens blank, an initial rough grind using a diamond ring tool is used. A series of progressively smaller grit diamond tools are then used to sub-aperture grind the aspheric prescription into the part.

LaCroix utilizes highly specialized CNC grinding technology to minimize mid-spatial frequency errors.

Once the optical lens is sufficiently ground, aspheric lenses are then initially polished to remove all subsurface damage induced in the grinding process. An iterative feedback loop is initialized by taking measurements with either a profilometer or utilizing 3D aspheric metrology on all aspheric lenses. This measurement is fed back to the aspheric polisher for a correction run. This process is repeated until form, and slope error specifications are met.

Technology

LaCroix Precision Optics is dedicated to maintaining state-of-the-art machinery and has recently made significant investments in the latest innovative aspheric technology. View our Advanced Processing page to learn more.

Coatings

We have extensive in-house coating capabilities to meet your requirements. See our coating capabilities.

Uses for Aspheric Lenses

- Night vision goggles

- Multiwavelength laser collimation

- Multi-spectral imaging

- Telescopes

- LASIK devices

- Machine vision

- Ophthalmology

- Threat detection

- Laser target designators

- Scopes

- High-power lasers

- 3D scanning and imaging