Key Takeaways

- Avantier’s small objective lens revolutionizes medical optical systems, particularly in dental health applications.

- This project focuses on utilizing a higher-resolution lens while reducing the overall optical system volume. This carefully balanced approach involves advanced optical design, material selection, and component layout optimization.

- The lens, with a diameter under 3mm, a length below 10mm, and a larger working distance, showcases exceptional performance without compromise. Avantier achieves this by incorporating integrated components, lightweight materials, and innovative design strategies.

- The lens’s advantages include: reduced size, weight, and enhanced imaging quality. These advantages contribute to a competitive edge in the market. Avantier’s small objective lens exemplifies technological breakthroughs, fostering innovation in dental healthcare and advancing the field of oral science.

Introduction

The small microscope objective lens is widely used in medical optical systems, particularly in oral cavity examinations, dentistry examinations, and dental nerve diagnostics. With a smaller size, higher resolution, and an intelligent AI-assisted system, it provides powerful tools to help healthcare professionals gain a more comprehensive understanding of oral health conditions. The application of this small objective lens in the field of dentistry highlights its importance in improving image resolution, in achieving precise diagnostics, and in advancing research in oral medicine. By offering advanced visual tools to doctors and researchers, this lens has made outstanding contributions to oral healthcare and oral science.

Project overview

Currently, most intramural scanner system brands require you to use specific scanning strategies or workflows to ensure optimal data collection. However, this project aims not only to utilize a higher-resolution small objective lens but also to reduce the overall volume of the optical system, providing ample space for the AI-driven three-dimensional model. In the end, Avantier’s small objective lens has a diameter of less than 3mm, an overall length of less than 10mm, and a larger working distance of more than 25mm.

Reducing the overall volume without compromising performance requires a careful balance of various factors.

Avantier strives to reduce overall volume while carefully balancing various factors in order to ensure that performance is not compromised. By employing advanced optical design and material selection and byoptimizing component layout and density, the minimization of volume can be effectively achieved. Simultaneously, the use of lightweight materials and highly integrated components enhances system efficiency and performance. In this process, engineers must meticulously consider the functionality and interrelationships of each element to ensure that the reduction in volume does not adversely affect the overall performance and stability of the equipment. By leveraging innovative technologies and design strategies, it is possible to maintain exceptionally high optical performance even in compact volumes.

- Optimized Design: Utilize advanced design tools and techniques to ensure that each component of the system is arranged and designed in the most efficient manner. Consider using lightweight materials and structures while ensuring strength and stability.

- Component Integration: Integrate multiple components, especially optical and electronic elements, to reduce the overall volume. Carefully designed integration can minimize gaps between components and enhance system efficiency.

- Performance Optimization: Emphasize maximizing performance in system design, enabling a more efficient use of space and an overall reduction in volume. This may involve optimizing the utilization of optical components, sensors, and other critical elements.

Lens performance

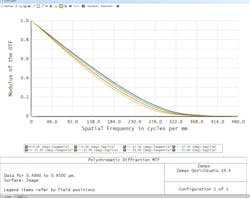

Through our carefully optimized design, our small objective lens exhibits significant advantages compared to leading companies worldwide. Firstly, we have successfully achieved the goal of reducing overall volume without compromising performance, thereby enhancing the competitiveness of our lens in the market. By incorporating more integrated components, we have effectively decreased the overall size and weight, freeing up substantial space for customers to integrate additional functionalities.

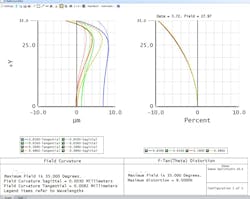

Secondly, we have meticulously optimized the optical system configuration and have utilized higher-quality lens materials to enhance imaging quality and resolution. The small objective lens offers a larger field of view, higher resolution, and an extended working distance, providing users with an outstanding observational experience. This not only elevates the expertise of our design and manufacturing teams, but this also delivers a more reliable tool for customers in the medical field, especially those with high demand for small objective lenses.

Specification

Wavelength range |

Visible Light |

Diameter |

<3mm |

Working Distance |

<25mm |

Field of View |

25mm x 25mm |

Image Quality |

@ Visible LightMTF >45% with 9 mm-1 Ronchi in object spaceMTF >80% with 3 mm-1 Ronchi in object space |

Conclusion

In this project, Avantier’s small microscope objective lens has demonstrated outstanding performance in medical optical systems. Through carefully optimized design, we have successfully reduced the overall volume of the lens while maintaining high performance, providing additional space for the integration of an intelligent AI-assisted system. Widely applied in fields such as dentistry, this innovative design enhances image resolution, enables precise diagnostics, and advances research in oral medicine. Avantier’s design not only achieves significant technological breakthroughs but also makes remarkable contributions to innovation in dental healthcare and oral science.