A laser line filter is a precision optical filter with an extremely narrow passband centered on a standard laser wavelength. These optical filters are used to prevent the distortion of measurement signals and to increase image contrast. They are used to screen out undesirable background radiation and ambient light.

Our laser line filters have applications in laser-based fluorescence instrumentation, as well as in Raman spectroscopy and in analytical and medical laser systems. Although laser light is usually considered in terms of a single, monochromatic beam with a single output wavelength, the real world picture is actually much messier. All laser sources include glows, plasma, or lower levels of transitions, and this scattered light can interfere with a clear reading with light detection instrumentation. Most laser sources also exhibit wavelength shifts when power or temperature changes. Laser cleanup filters are thus essential in eliminating unwanted light and transmit pure, thin-line energy.

At Shanghai Optics we manufacture laser bandpass filters with ultrahigh peak transmission, typically greater than 90%. These filters have excellent blocking (an optical density of greater than 5.0) from ±1% of the laser wavelength. The narrow bandwidth typical FWHM is less than 0.38% of laser wavelength.

Notch filters, which reject one specific band and transmit all other light, are also available.

Environmental Stability of Shanghai Optics Laser Line Filters

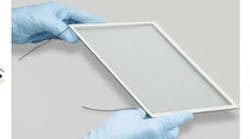

Our filters are dielectric coated with state of the art IBS technology. Since we use no adhesives, these laser optical filters are environmentally stable and have a long life span.

They are also temperature stable, and you can expect a center wavelength shift of less than 0.02 nm per degree Celsius. This miniscule change will be in the direction of the temperature change. When mounting your laser line filter, ensure that the highly reflective side of the filter faces the laser source. This protects the blocking glass and epoxies from thermal load.

Using Angle of Incidence to Fine Tune Your Laser Line Filter

The wavelength passed in a laser line filter is highly dependent on the angle of incidence of the laser beam, and this can be used to fine tune your filter to the exact wavelength your application requires. Increasing the angle of incidence will cause the center wavelength to shift to shorter wavelengths, and decreasing the angle of incidence will cause a shift to longer wavelengths. The shift can be calculated with the formula

λθ= λo [1-(no/ne)2 sin2θ]1/2

Here λθ is the new center wavelength, λo is the original center wavelength, and no/ne is the ratio of the index of refraction in the environment and in the filter. Note that in air no can be taken to be 1. In this formula θ is the angle of incidence.

Standard Specifications

Our state of the art metrology equipment allows us to ensure that every filter which leaves our factories fully meets all applicable standards. These laser line filters are manufactured of low fluorescence BK7 or an equivalent. Their peak transmittance is greater than 90%, and a typical FWHM (full width half maximum) is 0.38% of λc. The maximum FWHM is 0.7% of λc.

The clear aperture of our filters is greater than 80 percent, and the operating temperature of these filters from -45°C to approximately 85°C. Temperature dependence, within that interval, is guaranteed to be less than 5 5ppmr/°C.

Environmental durability meets MIL-STD-810F military standard requirements, and physical durability MIL-C-48497A. We offer black-anodized aluminum ring mountings for these filters.

Our factory standards ensure that the surface quality of each of our laser line filters is 60/40 scratch dig. Beam deviation is certified to be no more than 11 arc seconds. Diameter tolerance is +0/-0.1mm, and thickness tolerance is ±0.1mm. The thickness of our factory standard laser lenses is 3.5 mm, and we offer two sizes, Ф12 .5mm or Ф25.0mm. Light blocking is high, with an optical density (OD) of greater than 5.0 from λc ± 1.0% and an OD of greater than 6.0 from λc ± 1.5%.

Please contact us for manufacturing limits or to discuss custom orders. Our team is experienced in designing a wide variety of custom optical systems, and we welcome the opportunity to apply our expertise to your problem.