Antonio Castelo: What’s the backstory of your appointment as CEO of TRUMPF Photonic Components?

Berthold Schmidt: My career in photonics started more than 25 years ago. In 1998, after completing a Ph.D. in physics at the Technical University of Munich, I worked for a startup company that later became JDS Uniphase (JDSU) in Switzerland as a device development project manager. In 2002, the company was sold to Nortel Networks, and I became their manager of Advanced Devices R&D. Two years later, we were bought by Bookham, and I worked for them as a marketing manager until 2009, when I became COO and later CEO for Intense Ltd., a private equity-backed business designing, developing, and manufacturing semiconductor lasers and integrated subsystems for worldwide markets.Those 10 years were a great learning experience because I had to adapt to four totally different companies and management setups ranging from small startups to large companies, and I was able to analyze the methodology and take the best out of each one. I then worked briefly as a partner at Harder & Partner, Switzerland—an independent consultant for the high-tech industry with a focus on photonics, MEMS, and semiconductor devices. And in 2013, I joined TRUMPF as R&D coordinator and business development for TRUMPF’s Laser Marking Systems in Switzerland.

Two years later, I became head of TRUMPF’s corporate research, and in 2016, I was appointed CEO and president of TRUMPF Photonics in New Jersey. The next year, I became CTO of the TRUMPF laser technology department at the headquarters in Ditzingen, Germany, and in 2020, I was promoted to CEO of TRUMPF Photonic Components in Ulm, Germany.

Castelo: What are TRUMPF’s main products?

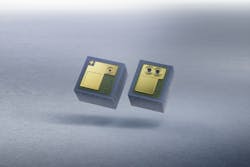

Schmidt: Established in 1923, TRUMPF is a family-run company. Our core business is machine tools and laser systems for industrial applications in the areas of cutting, welding, marking, and surface processing. We also provide vertical-cavity surface-emitting laser (VCSEL) solutions and photodiodes for numerous applications for the industrial sector and the consumer market—for example, in self-driving cars, smartphones, and optical data transmission.Our other products include power electronics, power tools, and a range of software that covers the entire production process. In recent years, TRUMPF transformed from being a traditional machine tool manufacturer to become more of a hardware and software and service organization offering connected products through which we strive to give our customers added value. We also have a laser business which offers full subsystem solutions for the semiconductor industry—for instance, for the Dutch company ASML. TRUMPF has more than 70 subsidiaries around the world, with a workforce of around 16,500 and annual sales of €4,223 million.

Castelo: How important is R&D?

Schmidt: At TRUMPF, we spend around 11% of turnover on R&D. We have an active information exchange among multiple research centers, which support us on the industrialization of laser systems because we cannot afford to miss out on technical developments that might be important for our broad range of photonics products. They ensure we maintain our technical leadership in the market.

Castelo: What are your main challenges as CEO?

Schmidt: One of my first interventions was to discontinue certain unprofitable activities. Coming in from the outside, I had a more neutral view—but when you tell employees that there isn’t really a business case for products they’ve been working on for two years, it’s difficult for them to accept. I wanted to streamline certain processes, to operate with more discipline and communication, and to introduce more data-driven decision-making. Fortunately, I had a great management team who understood and recognized the value of these principles, so it wasn’t really a fight—more a joint development by myself and the management team to transform the organization into what it is today.

Castelo: What are the main differences between consumer and industrial markets?

Schmidt: In some respects, they are similar. For example, in terms of meetings, checks and balances on the milestones, the product development process for a big laser system for a company like ASML is similar to developing a small laser diode for a high-volume consumer customer. In terms of high-quality standards, both customer groups are very demanding, as well. Product development for industrial customers tends to be more personalized, whereas for consumer customers we need to establish more standards early on. For both, it’s a collaborative approach with very large companies working directly with our engineering team, which at times can be challenging.

Castelo: What impact will the quantum era have on TRUMPF?

Schmidt: We will continue to be innovative, but careful. As far as technologies like quantum, we will continue to work with startups and research institutes, but we don’t see these technologies as near- or mid-term drivers of our core business. There’s a lot of investment going into quantum. At TRUMPF, we would rather take a cautious, but consistent approach to new technologies. What we are going after in the first stage is innovative particle and magnetic sensing that we can bring to the market for applications that can be used today.

This approach is similar to our activities in the VCSEL area. While we consistently bring products to the market for datacom and consumer sensing today, we’re also looking into the future, exploring the industrialization of a shortwave-infrared (SWIR) VCSEL above 1300 nm to conquer new application fields. Here, we see synergies in using our existing core technology and manufacturing equipment of gallium arsenide (GaAs) VCSELs, to also build up mass production for indium phosphide (InP)-based long-wavelength solutions.

Castelo: What’s your advice for the next generation of entrepreneurs?

Schmidt: First, you should never be shy about hiring people who are more knowledgeable than you. I’m continually amazed at how brilliant and gifted people in the photonics field are, and I’ve always made sure that such people have a place at TRUMPF and that everything is done to make them feel comfortable so they can be productive. I strongly advise seeking out gifted people who can make a change to your company and support you in your vision.

Second, very often, startups get lost in their technology. I often hear the argument that a technology is so new and groundbreaking that the customer doesn’t know they need it. When you develop a certain technology, it’s crucial to talk to customers at an early stage so you understand what they really want and how you can solve their problems. Unfortunately, this is something that early-stage companies often fail to do.