AXEL LUFT and SILKE PFLUEGER

Sometimes, reducing cost can also improve aesthetics and lead to better cars. Case in point: Implementing laser brazing for the ditch joint attaching the roof and the side panel of the car. Compared to laser welding or spot welding, laser brazing improves the aesthetics of the joint so dramatically that the ditch molding can be omitted. The consumer gains more benefits: Lighter, quieter, stiffer and safer cars, and no more extra plastic parts that can—and one of the authors speaks from experience—pop out and require a costly and unnecessary visit to the shop. Doing away with that extra part also means cleaner lines on the car and a lack of dirt-accumulating gaps due to a continuously joined surface.

History

The last two decades saw the widespread introduction of lasers into the body-in-white production lines. While Volvo and BMW were early adopters, Volkswagen quickly caught on and soon was on the forefront, installing hundreds of lamp-pumped Nd:YAG lasers in their Wolfsburg, Germany, and worldwide plants. The first laser joints were hidden or covered welds mainly implemented to reduce flange size and body weight and to obtain stiffer structures through the use of hydroformed pillars. These structural welds are still in use today. However, laser joining's advantages are most apparent in laser brazing of zinc-coated steel or the laser welding of aluminum with filler wire of class A show surfaces. For these surfaces, a low warpage, stiff joint ready for the paint shop with almost no post-processing makes it a unique process. Class A laser brazing of zinc-coated steel was first introduced in 1997 on the Audi TT. Joining the C-pillar to the rear quarter-panel enabled the use of the same part for both the convertible and the coupe and on the VW Bora deck lids that had to be stamped from two parts and then be joined.

Equipment considerations

Uptime is the number one consideration for any equipment on the floor of an automotive factory. A typical requirement is >99.5% uptime, and a maximum of 30 minutes to get equipment up and running again. While this is a long way from telecom equipment-like reliability, it is quite challenging for industrial laser systems and was one of the initial major issues. It is typically solved by a two-pronged approach: a reliable laser combined with a viable back-up strategy.

Many plants employ so-called "laser farms", where all the lasers for a production line are put in a central, environmentally controlled location, typically on a mezzanine. The locations of the laser used on the floor are usually spread throughout the plants, requiring very long optical fibers and advanced controls via a plant network for the beam delivery solution. When lamp-pumped Nd:YAG lasers were the only industrial laser available, this was the best solution. These systems were bulky and inefficient, and that required frequent scheduled and unscheduled maintenance.

The latest generation of industrial lasers—fiber coupled diode lasers, fiber lasers, or disk lasers—are all diode based, and have a better inherent reliability. In new installations, diode lasers are typically located near the laser cell (see FIGURE 1). The back-up strategy is usually based around additional fibers and beam switches that allow time share with up to 6 fibers, which—at the expense of cycle time—can be used to serve multiple cells or both sides of a car body in case of an outage of one system. Mounted on casters, it's also possible to quickly move a spare laser to the laser cell while the other laser is being repaired without the time pressure of repairing it on the production floor.

Multi-kW lasers mounted on casters are a sign that another requirement of the automotive industry has been tackled. Designing lasers that are smaller than many American household refrigerators is only possible because of improved wallplug efficiency. Disk and fiber laser have 25% and 30% efficiency, respectively, whereas fiber-coupled diode lasers for brazing can reach up over 40% wallplug efficiency. This reduces the size of the auxiliary components like power supplies and cooling systems in the lasers, thus reducing overall size. It also means that external cooling requirements are dramatically lowered compared to lamp-pumped systems, with chillers placed inside or next to the laser generators.

Brazing speed improvement

Diode lasers made their debut as a brazing tool in the manufacturing of the tailgate of the Audi A3. Typical process speeds were initially 2.4 m/min. To increase production figures, Volkswagen set a goal of improving brazing speed without compromising quality. At the VW Touran production line in Wolfsburg, a process comparison was conducted between an Nd:YAG laser and a fiber coupled diode laser. While the existing YAG laser used a defocused beam, the new diode laser was set up with the beam in the focus position and a 3.2 mm diameter focus.

Both the brazing speed and the joint quality were increased using the diode laser. By working in the focus of the top hat laser beam, a better distribution of the power density into the boundaries of the joining partners can be achieved. With the 6 kW diode laser, edge notches were reduced by 75 percent, and maximum process speed increased to 4.4 m/min. Volkswagen decided to replace all YAG lasers used in the Touran brazing applications with diode lasers.

Aluminum show surfaces

Welding of aluminum body-in-white structures with filler wires is the natural next step for many automotive companies dealing with the challenges of joining aluminum, using much of the same process knowledge. The joint styles are virtually identical, and the same processing heads are used. A test set-up for a deck lid application using a fiber coupled diode laser with a tactile process head is shown in FIGURE 2.Diode lasers offer a distinct advantage for aluminum joining: At 900 to 1060 nm, the wavelength of the diodes is closer to the absorption peak of aluminum than the 1030 nm of disk or 1070-1080 nm of fiber lasers. After a multi-year development project, Audi decided to use a 4 kW diode laser with a 400 µm fiber to weld the tailgate of the Q5 and is running this system on their production floor.

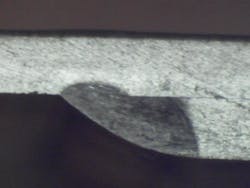

Kuka North America has successfully used a 4 kW / 400 µm laser and a 6 kW / 1000 µm laser, depending on the joint requirements. Typical weld speeds are 3 to 4 m/min. The 1000 µm fiber is especially useful for an edge lap weld requiring weld strength yet very little to no show on the backside (see FIGURE 3).Laserline's (www.laserline.de) applications lab in Germany has performed extensive multi stitch testing which proved the diode laser weld process robust against several millimeters of changes in focal position and several degrees of variation of the weld angle. It also shows the robustness of the fiber coupled diode lasers against back reflections.

Conclusion

Catering to the reliability needs of automotive manufacturing plants, a new crop of near IR lasers is now enabling new design opportunities on auto bodies. Diode laser brazed parts meet the highest specifications for optical quality of a visible joint without further post-processing. Excellent process stability, high speed, reliability and cost advantages have resulted in fiber coupled diode lasers being utilized in many new body-in-white applications.

Axel Luft ([email protected]) is with Laserline GmbH in Germany. Silke Pflueger ([email protected]) is with Laserline Inc. in Santa Clara, California.