The global mobility transformation is in full swing, with demand for electric cars and alternative drive components continuing to rise. In particular, the focus is on high-performance components that flow directly into the production of batteries, e-motors, and power electronics for electromobility (e-mobility).

Companies, mainly automotive suppliers, want new manufacturing solutions and technologies to enable alternative drive concepts. Many of these designs require new or enhanced joining processes and lasers are the tool at the center of many of these solutions. Lasers are extensively used to connect battery cells to form modules or packs, ensuring gas-tight joints and crash safety in battery packs and thermal management systems. The versatility and flexibility of lasers in surface preparation for joining can be shown by using an e-mobility battery pack as an example, where the use of novel laser and system developments are currently being industrially realized.

Battery packs are the key component in e-mobility and account for about 40% of the value added to a battery electric vehicle (BEV), making it an important development area for automotive manufacturers. The expected high volumes of the battery pack pose new challenges to the entire automotive market, including suppliers, because a volatile market environment must be reconciled with diverse technical requirements, such as gas tightness. This results in increased technical requirements for joining, and a growing need for surface preparation.

A clean, even surface is a basic requirement for successful and durable welding and adhesive connections. In industrial environments, components often become contaminated, oxidize, or are covered in protective layers before the joining process. Lasers provide a remedy for this as a noncontact tool that rapidly cleans components of dirt and oxidation or removes functional layers within seconds. It does this selectively only in areas where joining is meant to take place, for example, or where the functional layer or coating is no longer needed.

Looking at the individual components of a typical battery pack, we can highlight various application examples where laser surface treatments are used, including ablation for electrical contacting, cleaning for welding, cleaning/structuring for gluing, and structuring for metal-plastic bonding (see Fig. 1).

To gain a better understanding of the applications, it is important to appreciate the difference between laser cleaning, laser ablation, and laser structuring. All of these processes are typically carried out by solid-state infrared (IR) nanosecond lasers such as TRUMPF’s TruPulse nano and TruMicro 7070 laser sources.

In the laser cleaning process, the focused laser beam removes contaminants such as hydrocarbons or oxides that could adversely impact the joining process. The laser evaporates undesirable layers using very high peak-pulse power, in a controlled manner so as not to damage the substrate material. Optimization of the laser pulses ensures there is virtually no thermal effect on the workpiece surface, preventing distortion or damage/changes to the material/component (see Fig. 2, top).In ablation, the layer to be removed is heated by laser energy and evaporates or sublimates as in paint or thin-film removal (see Fig. 2, middle). The transparent material is ablated in its solid state.

With laser structuring, regularly arranged geometric textures are generated on targeted surfaces in a reproducible way using pulsed laser radiation. The laser beam melts the material in a controlled manner, solidifying it into a defined structure based on optimized pulse parameters and optical beam manipulation techniques such as wobbling.

The battery pack cover encloses the battery cell hermetically and provides electromagnetic shielding. During production of the cover, paint and oxide layers are removed by a laser-based ablation process (paint removal), which is necessary for technical cleanliness of the joint connection or to enable electrical connectivity and electromagnetic compatibility (see Fig. 3). The cover plate is usually made of aluminum (e.g., 5000 and 6000 series) or steel alloys with a cathodic dip coating.Localized cleaning for welding preparation is required to provide a clean surface free of debris, oils, and corrosion for optimal welding results. This can be critical to maintaining battery pack welding quality and gas/water-tight sealing.

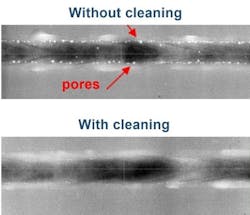

To meet requirements for steel and aluminum, welds must not have any defects irregularities, or pores. Increasing amounts of porosity lead to reduced weld strengths and leaks. Spatter and porosity are caused, among other things, by residual lubricants such as greases and oils, as well as rust and other oxides. These potential contaminants can be eliminated by a preceding laser cleaning process before welding. Experimental results show a significant reduction in porosity when laser cleaning during laser welding of aluminum, resulting in higher-quality weld seams (see Fig. 4).Adhesive bonding is increasingly used for aluminum alloys in automotive manufacturing due to uniform load distribution, improved joint stiffness, energy absorption, and its ability to act as a galvanic isolator for dissimilar material joints. For adhesive bonding, surface preparation is an important part of the process chain. Laser treatment is an effective and environmentally friendly option.

Laser cleaning and structuring are reproducible and effective technologies that can increase the adhesive bonding strength in subsequent joining processes. The laser cleans the surface from dirt and oxides and promotes the rapid passivation of the surface, which creates a shell against further chemical decays. The modification of the surface chemistry and creation of a more uniform and thicker aluminum oxide layer is likely to be another contributing factor to the improved bond performance.

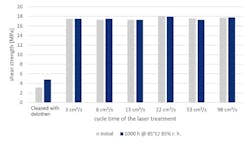

Laser treatment can increase the shear strength of an adhesive bond from 3 MPa to more than 17 MPa in the initial state; after an exposure time of 1000 hours at 85°C, the strength can be increased from 5 to more than 17 MPa (see Fig. 5). The process window for laser pre-treatment appears to be robust. Different cycle times were set with different parameters, including laser power, spot size, and frequency. All parameters show identical shear strengths. The requirements of an adhesive bond with high cycle times and correspondingly high laser powers of up to 2000 W, as well as slower cycle times with laser powers of up to 300 W, can be achieved.Cleaning/structuring for metal-plastic bonding

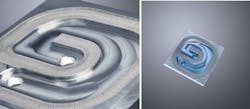

There is a growing need for direct metal to plastic bonding, which is enabled by laser surface structuring. In the battery pack example, the thermal management system creates optimal operating conditions for its reliable and effective use. A thermal management component was selected as a demonstration component (see Fig. 6), and this heat exchanger serves as a cooling system by constructing cooling channels in the component. This component was used to demonstrate the capability to generate a gas-tight connection of up to 5-bar maximum pressure load using a metal-plastic connection.Beyond meeting the requirements for gas tightness and the obtainable maximum pressure, this part also demonstrates the simplicity of the process chain for manufacturing metal-plastic connections. The use of the polymer also generates numerous technical benefits as it reduces the weight of the demonstrator, provides electrical insulation, and allows direct visual inspection of the cooling channels.

One method for the metal-plastic connection is direct thermal joining which is a two-step process. In the first step, the metal surface of the joining partner is modified or structured using a pulsed laser. A laser creates a textured surface by using high-energy pulses to locally melt the metal in a process that results in a locally roughened surface. This surface structure enables the plastic partner to grip the metal surface.

The second step relates to the actual joining of the materials. The metal surface is heated by induction so the plastic melts at the interface. The molten plastic is wetted by pressing it against the metal partner. With these two steps, a mechanical interlock is created. After self-quenching or active cooling, the component can be rapidly loaded to subsequent assembly steps.

A typical laser cleaning system used in battery pack applications consists of a nanosecond-pulsed laser combined with scanning optics. The short laser pulses are guided from the beam source to the processing location via an optical laser cable. The beam is guided via a flexible optical laser cable or other suitable beam guidance components. This enables easy integration in manufacturing systems. The advantages and benefits of the surface treatment with the laser compared to conventional methods such as chemical baths or mechanical processing are listed in “Benefits of laser surface treatment” (see below).

Nanosecond lasers are available in different versions. One difference is the maximum average laser power, which varies from 100 to 2000 W. You can influence cycle times, for example. There is a suitable laser with the right properties for every application, and there is also an optic with integrated localized exhaust/fume extraction that may be required for applications such as paint stripping (see Fig. 3, right).

Lasers are an effective, environmentally friendly, and flexible tool for surface processing. They can clean and remove paint, as well as generate surface textures. For welding or electrical connectivity, a technically clean surface is necessary, while for bonding a certain surface structure or activation is applied, and for a metal-plastic connection a rough structure texture is required. Today’s nanosecond lasers are providing proven industrial solutions to enhance joining and bonding processes.