Seeking to overcome challenges inherent in laser glass and polymer cleaving, researchers at Fluence (Warsaw, Poland) developed a streamlined technique using ultrafast femtosecond fiber lasers. The method delivers direction-independent cleaving with high-quality edge and reduced kerf width at high speed—achieving meters per second even for thick glass—and produces no debris/fume, making it environmentally friendly.

Tests show the approach works with various materials, including sapphire, and most glass applications in the display and consumer electronics markets, such as cover glass for mobile devices and Ultra-Thin Glass (UTG) for foldable displays. For UTG, the results demonstrate that achieving a surface roughness below 100 nm is possible only using 250 fs pulses.

In polymer processing, particularly medical-grade polylactide (PLA) and PMMA, the technique based on pulses shorter than 250 fs helps to overcome the heat accumulation problem and, thus, the low cutting speed of thick polymer substrates. The researchers demonstrated cutting speeds of a few orders of magnitude faster compared to the typical polymer ablation cutting process.

Specifically, the experiments, which tested various parameters, including pulse duration, burst energy, number of pulses in the burst, and pitch when cleaving diverse materials, demonstrated three results:

1. The influence of process parameters on the edge quality of various materials cleaved in a crack self-orientation regime.1 Edge roughness affects the strength of the material after processing, which is critical for applications like foldable displays.

2. The possibility of cleaving in any direction at high speed, such as when manufacturing round shapes, without active beam steering, while achieving a high-quality edge regardless of the direction.

3. The ability to use the same simplified setup and laser source to cleave glass and polymers.

Experimental setup

The researchers used the company’s Jasper X0 femtosecond fiber laser operating at an average power level of 20 W, with an available output of 100 μJ pulse energy in a single short pulse at 200 kHz and using a fundamental wavelength of 1030 nm.

The tests included cleaving 50- and 100-μm-thick UTG (see Fig. 1), 1.1 mm thick BK7 glass, double-side laminated UTG, PLA of 0.3 mm, and PMMA up to 3 mm thick. The roughness was measured using a LEXT OLS500 laser confocal microscope.

The researchers used a previously reported omnidirectional microcrack orientation technique1 that ensures microcracks undergo self-orientation along the cutting trajectory, making it possible to cut in any direction without rotating optics in a beam path or masking.

Attaining ultra-high-quality UTG cleaving

To test UTG cleaving, researchers compared the self-crack orientation regime using picosecond pulses with the new regime using several parameter sets. The results demonstrated that a short pulse duration of 250 fs, the shortest femtosecond pulses that Jasper X0 laser can generate, and a well-optimized pulse pitch could easily separate 50- and 100-μm-thick UTG, creating an edge roughness below Sa = 0.15 μm—essentially a glossy edge. Researchers note that modifying the laser parameters according to UTG thicknesses is necessary to achieve the highest quality.

Bogusz Stepak, R&D director of laser microprocessing at Fluence’s Ultrafast Laser Application Laboratory, believes the roughness likely is even lower than that measured because it’s at the limit of the microscope. The very-low edge roughness is beneficial because “there is a very strong correlation between the roughness and UTG bending strength,” says Stepak.

Interestingly, the novel approach does not generate microcracks and is impossible with picosecond pulse durations. “After the pulse deposition, the energy relaxation inside the material doesn’t cause cracking,” Stepak says. “This is a different type of modification, and if we make those modifications close to each other, we can create a homogenous line of modified glass and break along this modification to get a very high-quality edge.” However, more testing is necessary to understand fully why the process works the way it does and to test the cleaved glass’ strength.

When applying the same setup to a hybrid material, a 90 μm UTG glass core sandwiched between two 30 μm polymer layers, the team was able to break the material using both 250 fs and 8 ps pulse durations, but the edge quality made with 250 fs was significantly higher.

Additionally, the method could cleave the material in a single pass with no post-processing, delamination, cracking, or surface contamination.

Processing BK7

For the 1.1 mm-thick borosilicate glass, researchers cleaved a round shape using the femtosecond laser using various parameter sets, including different energy levels, pulse pitches, and numbers of pulses in the burst. Slight changes of either affect the quality. However, at three or four bursts with a pulse pitch of 5.0 to 7.5 μm, “we found that there is a sweet spot for pulse pitch to obtain very high-quality surface roughness below 0.4 μm, which is typically enough for most industrial applications,” Stepak says.

The team measured the roughness for horizontal and vertical cuts to evaluate that this process produces the same quality regardless of cleaving direction. The roughness was similar for both. “So, we have this very simple setup without any rotating parts, and we have the same quality for all directions,” Stepak says. “It’s a very high-quality process that provides easy separation.”

Stepak added that using a higher pulse pitch enables increased processing speed. At a 100 kHz repetition rate, both UTG and, generally, glass of up to 1.5 mm thickness can be processed with a single pass at a speed of up to 1 m/s. With a 60 W Jasper X0 laser operating at 300 kHz, it is possible to triple this value.

Processing polymers

Researchers used the same techniques for cleaving 0.3-mm-thick PLA and PMMA with thicknesses up to 3 mm with promising results, explains Stepak. They found that the easiest mechanical fracture was obtained for the shortest pulses of 250 fs (see Fig. 2). When using picosecond pulse duration, breaking the samples was nearly impossible.

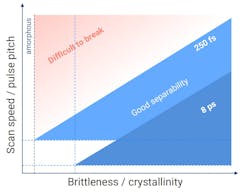

Different materials require different pulse pitches to obtain good results. “So for semicrystalline polymers, like polylactide, we can make the cleaving with a higher pulse pitch because the material is more brittle,” Stepak says. “If the material is less brittle—for example, PMMA, which is a completely amorphous polymer—we need a lower pulse pitch.”

“Using very short pulses and the same optics as for glass, we can make the cleaving of the polymer,” Stepak says. “And, again, we don't have a kerf, we don't have material loss and fumes, and we virtually have no heat-affected zone, so this is a very good process, especially for demanding applications like medical.”

The technique shows potential for use in various amorphous (PMMA, PC) and semicrystalline polymers (PET, PLA, PA6, PE, PEEK; see Fig. 3). Future tests will explore other processing regimes to discover how to further optimize the cutting quality and speed of various materials and apply the process to create more complex shapes of the edge.

REFERENCE

1. B. Stepak, N. Grudzień, K. Kowalska, Y. Stepanenko, and M. Nejbauer, J. Laser Appl., 35, 012005 (2023); https://doi.org/10.2351/7.0000798.