For numerous purposes, the ideal high-power laser would achieve the highest brightness possible—that is, single spatial-mode output. While high-power, high-brightness lasers have come a long way in the past couple of decades, the highest power output of a single-mode laser still reaches up to “only” around 10 kW. To achieve higher powers with single-mode beam quality for purposes such as military weapons and some types of materials processing, the only way to go higher is to use beam combining.

One straightforward method to do this is spectral beam combining, in which dichroic mirrors are used to spectrally combine the beams of two or more lasers emitting at different wavelengths. While this has the advantage of simplicity, it is limited by the number of high-power single-mode lasers, each of different wavelengths, that can be obtained.

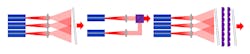

The more difficult method, and the “holy grail” of this type of technology, is coherent beam combining (CBC), which theoretically allows any number of lasers, all coherent with respect to each other, to be combined into a lone single-mode beam. In actuality, light from a single seed laser is split and sent into a number of amplifiers to create numerous beams that are all coherent with respect to each other before combining. Existing ways to combine the beams are of two general types: tiled aperture, and filled aperture (see figure). In tiled aperture, the near-field laser beams are all placed next to each other, creating, in the far field, a single beam (although usually with unwanted diffraction orders) with real-life efficiencies of up to about 50%. In filled aperture, two beams are combined coherently with a beamsplitter; the resulting beam can be then combined with another pre-combined beam, and so on, with efficiencies of up to 90% or more—with the disadvantage of requiring many precisely aligned concatenated optics to achieve the combination.

Mixed-aperture approach

Now, researchers from TRUMPF (Schramberg and Ditzingen, Germany) and Leibniz Universität Hannover (Hannover, Germany) have come up with a novel coherent beam-combining approach that is neither tiled aperture nor filled aperture, but is instead a combination of both. The approach uses a pair of microlens arrays (MLAs) that achieves good combination even at a low fill factor.1

It is easiest to understand how it works by first imagining the two MLAs in a more conventional application for them—a beam homogenizer. When a pair of MLAs is used to homogenize a laser beam, good homogenization is achieved only if the beam is not of single-spatial-mode quality; if the beam is indeed single-mode, the result will be discrete diffraction orders, rather than a nicely homogenized beam. The TRUMPF approach simply reverses this setup and places the array of beams to be coherently combined at the locations of the diffraction orders; if things work right, a single coherent beam will be the result.

Due to the geometry of the approach, which the researchers call “mixed aperture,” the input laser beams do not have to be placed laterally right next to each other to achieve high combining efficiency, and also do not require a concatenated optical setup—thus combining the advantages of the tiled and filled-aperture approaches, while eliminating their disadvantages.

In a proof-of-principle experiment, the beam from a mode-locked ultrafast laser emitting at 1.03 μm with a 10 nm bandwidth was split into 25 beamlets, which were sent at a low fill factor through the mixed-aperture beam combiner, resulting in coherent combination at an efficiency of 90%.

The researchers believe that the method can be straightforwardly scaled to higher numbers of beam channels, potentially leading to very high-power beams.

REFERENCE

1. M. Prossotowicz et al., Opt. Lett. (2020); https://doi.org/10.1364/ol.414388.