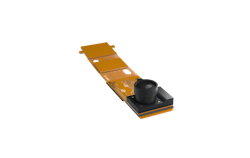

What do we really know about the air we breathe? To answer this question, Bosch Sensortec and TRUMPF are exploring a radically new solution. The result is the world’s smallest particulate matter sensor tiny enough to fit inside a smartwatch (see Fig. 1). Its secret? Optical technology.

Particulate matter became a hot topic about 10 years ago, and many countries around the world are now seriously concerned about the health hazard it poses to urban dwellers.

Particulate matter comprises particles so small they remain suspended in the air for a long time rather than sinking to the ground like larger particles. Coarse particulate matter (PM10) is defined as particles with an aerodynamic diameter of 10 µm or less. Particles with an aerodynamic diameter of 2.5 µm or less are designated as fine particulate matter (PM2.5) and pose a greater health hazard than larger particles. Once particulate matter is inhaled, it often remains lodged in the lungs, where it can directly cause damage or pass into the blood. The smaller the particles, the more likely this is.

Research shows road traffic and exhaust emissions are major causes of particulate matter within the atmosphere. Yet particulate matter levels are often much higher indoors, where frying food, burning candles, or wood-burning stoves can be significant sources of particulate matter.

Peter Ostertag, Director of Optics for Bosch Sensortec, recalls how the issue first rose to prominence, back in 2014. “All of a sudden, everyone was talking about particulate matter, and we thought it would be great to have a portable device telling you about PM levels wherever you happened to be,” he says. “Mean values, measured centrally, are nowhere as relevant to my health as what I’m actually inhaling at any given moment.”

Measuring particulate matter with a VCSEL

A portable laser system must meet several requirements: it needs to be small, pose no hazard to the eyes, and be low energy (operate at minimal laser power).

While on the lookout for a suitable partner, developers at Bosch Sensortec recalled a past project with Ralph Gudde. Back then, Gudde worked for the photonics arm of Philips, which has since become part of the TRUMPF Group and now operates under the name of TRUMPF Photonic Components.

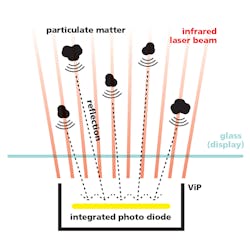

Gudde is an expert in vertical-cavity surface-emitting lasers (VCSELs), which are mini laser diodes that produce laser light with a high-quality beam. Requiring a power input of only a few milliwatts, they are phenomenally efficient and can be miniaturized down to the micrometer scale. Beyond emitting a laser beam, VCSELs with an integrated photodiode also capture the reflected light signal and convert it into a measurement (see Fig. 2). Known in the industry as a “ViP,” a VCSEL with integrated photodiode is unaffected by sunlight, which makes it suitable for outdoor applications.For Bosch Sensortec, the initial project with Gudde highlighted the potential of VCSEL technology. “I knew straight away it could also be used to measure particulate matter,” says Gudde. “It didn’t take long to build a demonstrator. We tested it on a modified lab rig at Bosch, using it to detect smoke from an incense stick. And sure enough, it worked.”

Contactless measurement

The particulate matter sensor from Gudde and Ostertag exploits a self-mixing interferometry (SMI) method, in which a VCSEL is used to scan the surrounding area with an infrared laser. If the beam hits particulate matter suspended in air, the VCSEL’s optical resonator captures the light reflected from the particles and mixes it with other light in the resonator. An integrated photodiode measures the resulting interference. Based on the difference in frequency, the system is then able to calculate the size and concentration of particulate matter in real time (see Fig. 3). This optical procedure reliably detects particles of 2.5 µm in diameter or even smaller.“This measurement takes place without any direct contact with ambient air, which means the laser can be installed behind a transparent barrier such as a display screen, and then used to detect particulate matter in the air beyond,” Ostertag says.

Unlike other sensors used to monitor air quality, the system does not need to extract an air sample and funnel it along a measured path. Instead, it directly measures any particulate matter floating in the ambient air. In other words: it doesn’t need a fan and can be installed within a hermetically sealed housing.

Why is this important? “A fan extracts not only particulate matter from the air, but also larger particles of dust and moisture. Just open a particulate matter stack after a couple of years and look at all the gunk and even insects that get sucked in by the ventilator fan. But with an optical sensor, you never need to clean or service it,” says Ostertag. “And a fanless design makes it silent. You can have a bunch of sensors working around you and still be able to read a book in peace.”

450X smaller

The fanless principle also enables a more compact design. “Our thinking was to make the sensor even smaller by incorporating multiple lasers,” Gudde says.

Bosch loved the idea, “because a smaller design meant we could also start thinking about wearable devices,” says Ostertag. “And it provides the perfect sensor for people on the move, integrated into a cellphone or a smartwatch.”

The two teams explored the idea of using multiple lasers and a sophisticated algorithm to interpret the reflections from particulate matter in ambient air and, in this way, determine the number and size of the particles.

Before long, they built an initial demonstrator, and tests soon confirmed they were on the right track. In fact, they achieved a measuring accuracy otherwise delivered only by devices 450X larger than the new optical sensor. “Instead of the size of a matchbox, we’re talking about smaller than a match head,” says Ostertag.

The particulate matter sensor is a mere 4.2 × 3 × 3.5 mm in volume, functions reliably within a standard temperature range, and delivers accurate results in real time. Product development is underway, with release of a new PM2.5 sensor scheduled for spring 2024.

Mini smart-home helper

Since it is compact and easy to integrate, the PM sensor is suitable for many applications where particulate matter poses a health hazard. “You could install the sensor behind the display of a smartwatch or smartphone, where it can measure the air through the glass screen,” says Gudde. “If it detects an elevated level of particulate matter, you would then be warned to leave the location or take other precautionary measures. I would love to use it to test my kids’ journey to school.”

Beyond mobile applications, the sensor can also be an asset when installed in fixed devices because particulate matter levels are often much higher indoors than outdoors. “If I’m frying something on the stove, particulate matter levels can quickly rocket to a hundred times the limit of what’s healthy. With a PM sensor installed in the hood, the extractor fan can be automatically controlled to reduce the concentration of particulate matter to an acceptable level. Given the high fat and moisture content of the air under the extractor hood, the use of a fan-based sensor would be problematic.”

For initial applications, Ostertag sees big potential in smart-home solutions—a window that automatically opens, or a ventilation system that automatically starts when a critical concentration of particulate matter is detected. The sensor is so small it can be discretely incorporated into wall thermostats or radiator valves.

This technology continues to fire the imaginations of development teams at Bosch Sensortec and TRUMPF. “We see a lot of potential for ViP/SMI,” says Ostertag. “And we’re already thinking about other applications that can help simplify our lives.”