Beginning decades ago with the dye laser, tunable coherent sources have been a critical enabling technology for performing high-sensitivity spectroscopic measurements across a variety of applications, including photochemistry, life sciences, and remote sensing. The advent of optical parametric oscillators (OPOs) provided a more-reliable solid-state alternative to dye lasers, offering a wider tuning range and greater reliability.

However, first-generation OPOs were physically large, relatively expensive, and somewhat temperamental. As a result, laser developers have sought to simplify these systems to make them more readily usable to the widest spectrum of engineers and scientists—that is, to end users who are not "laser jocks."

Ultimately, the goal has been to reduce the laser's true cost of data (the time, labor, and materials required to acquire a given data set when running an experiment). This makes the laser a more economically attractive tool for a larger number of applications, and is an especially important factor for life-science applications that scientists are aiming to move from the laboratory to clinical use. Another important design goal has been to improve the reliability and ruggedness of these systems.

Shipping OPOs by standard methods

In pursuit of this goal, Opotek (Carlsbad, CA), a manufacturer of tunable nanosecond sources, set out to produce an easy-to-use, highly reliable OPO, and to offer rapid worldwide service for it. However, the company didn't have the resources to set up numerous fully equipped service centers around the world, and so developed a novel design approach to their latest OPO series (the Opolette).

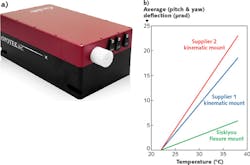

"We wanted to build a better self-contained OPO, including its own pump laser. And, we wanted to take full advantage of the new generation of miniaturized Nd:YAG pump lasers from Quantel to build the most compact nanosecond OPO ever—about the size of a shoebox," says Lam Nguyen of Opotek.

By making a small, ruggedized OPO, the company aimed for a product that could be safely and economically shipped by standard methods (such as postal services or FedEx) to anywhere in the world. The customer would then turn it on with no need to wait for on-site "commissioning" by company personnel, and then run the OPO for years without technical service or repairs. This would enable a fast-service model, where any problems that do occur are solved by express shipping the OPO back to the factory, followed by a rapid fix, and then express shipping back again. "An unusual business model for a complex scientific laser, yes, but much faster than waiting for a service visit, particularly in remote locales," says Nguyen.

The challenge was that OPOs are nonlinear devices that are extremely sensitive to misalignment. Because this particular OPO incorporates its own pump laser, it includes numerous adjustable optical mounts, both intracavity and between the pump and OPO. These must be immune to thermal drifts and to typical shipping and handling physical disturbances, as well as stable under operating conditions. Even slight movement of a mount and Opotek's approach to shipping and remote service would be in trouble.

To get the required stability, Opotek's engineers chose novel monolithic flexure mounts from Siskiyou (Grants Pass, OR). These flexures are each machined from a single piece of metal, in contrast to traditional assembled flexure mounts, which include at least two plates, two leaf springs, and so on. While traditional designs usually contain two or three different metals, each having different thermal expansion coefficients (causing drift and thermal cycling), a monolithic flexure avoids such thermal-mismatch problems.

Opotek reports that of the hundreds of these OPOs shipped, only three have not worked fine out of the box. In accordance with the company's intent, these were immediately shipped back, factory re-aligned, and returned to the customers, where the three are now working perfectly. By ruggedizing tunable OPOs to the point that they become shippable components, the company claims the result is a much broader user base, particularly in applications like life sciences and analytical measurements, rather than just traditional OPO applications such as spectroscopy and photochemistry.