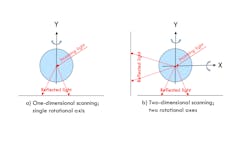

A microelectromechanical systems (MEMS) mirror’s basic function is to deflect and move a focused beam of light upon exposure. The light beam can be moved along a single axis (one-dimensional mirror) or in two axes (two-dimensional mirror). (See Fig. 1.) This simple action of receiving and deflecting a focused beam of light is at the core of scanning technology that is experiencing growth in numerous applications, which was unthinkable until recently.

Three competing design methods for making MEMS mirrors

Technology for making MEMS mirrors matured during the last decade with three main competing design techniques, which are classified based on the driving principles used to move the mirrors. They are: electrostatic driving, electromagnetic driving, and piezoelectric driving. All three have pros and cons and a comparative summary of them is shown in Figure 2.

All three techniques use silicon as a core material to make MEMS mirrors, although some of them need additional material to make mirrors move. In the case of electromagnetic driving, for example, a magnet is needed. In the case of piezoelectric driving, lead zirconate titanate (PZT) films are needed. Customers need to consider key performance parameters for given applications before choosing a MEMS mirror.

The choice of MEMS mirror size depends on the targeted application. A survey of MEMS mirror manufacturer websites shows that MEMS mirrors today range from 0.5 mm up to 10 mm in diameter. The majority of mirrors are in the circular shape, while some are elliptical.

New applications

MEMS mirrors have been used mainly in a few applications such as optical switching in telecommunications, optical projectors, and specialty applications like biomedical optical coherence tomography (OCT). However, this is changing as new applications pop up constantly.

The capability of MEMS mirrors to move light is ingeniously used to create two basic groups of products that are driving the majority of new applications. The two groups of products are: Laser projectors for animated visual messaging and video projection, and LiDARs for three-dimensional (3D) perception sensing.

Laser projectors convert moving light into higher-level information for practical use as signs, graphics, and videos. The information itself can be presented in vector graphic laser projection (VGLP) mode or in raster mode, and the use of MEMS mirrors is critical for both. VGLP based on MEMS mirrors (MEMS VGLP) is currently garnering attention because of its ability to produce high-contrast images in daylight outdoor conditions, which creates a pathway to many new applications.

LiDAR products use multiple technologies today. One of the solutions are MEMS LiDARs, which convert scanning and moving light into 3D information about the surrounding environment that can be used in different applications. The use of MEMS mirrors for scanning in MEMS LiDARs leads to product miniaturization, lower power consumption, performance improvement, and cost reduction.

Beyond this, a fusion of MEMS mirror scanning technology with other technologies can lead to new products with capabilities not otherwise possible. An excellent example is a fusion of MEMS mirrors’ scanners with cameras, which led to the creation of products for 3D metrology that is being rapidly adopted for precision manufacturing. This group of products offers miniaturization, fast measurements with the high resolution of a few microns, and low cost.

Automotive applications

Technology development in microelectronics combined with many sensors during the last couple of decades has led to massive adoption of semiconductor devices by the automotive industry. Today, a single car has approximately 1500 semiconductor devices, all of which work in tandem to improve either car performance or safety. Safety has become a new mantra and numerous new features are used in the car under the umbrella known as advanced driver-assistance systems (ADAS). Many have already become a standard feature and are a fertile ground for use of MEMS-mirror-based systems. Key applications include:

- Automatic emergency braking (AEB)—MEMS LiDAR is used

- Pedestrian detection (PD)—MEMS LiDAR is used

- Robotaxi as an autonomous driving service—MEMS LiDAR is used

- Dynamic Laser Headlight (DLH)—a MEMS-based white-light projector is used

- Heads-up display (HUD)—MEMS VGLP is used

- Courtesy lights—MEMS VGLP is used

Nonautomotive applications

Opportunities within the nonautomotive market for MEMS mirrors, MEMS VGLP, and MEMS LiDAR are also numerous (in our classification, the nonautomotive market includes industrial, telecommunications, commercial, consumer, and medical market segments). Key applications include:

- Extended/augmented/virtual reality (XR/AR/VR)—MEMS mirrors

- Biomedical/optical coherence tomography (OCT)—MEMS mirrors

- Telecommunications/free-space optical communications (FSOC)—MEMS mirrors

- Precise manufacturing and 3D metrology—MEMS mirrors

- Optical switching—MEMS mirrors

- Smart city—MEMS LiDAR and MEMS VGLP

- Robotics—MEMS LiDAR and MEMS VGLP

- Transportation/railway/buses—MEMS LiDAR and MEMS VGLP

- Holiday lighting—MEMS VGLP

MEMS mirror avalanche

The expected volume explosion of MEMS mirrors comes from the many applications using multiple MEMS-mirror-based systems or system solutions with multiple MEMS mirrors.

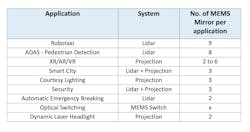

Figure 3 shows examples of multiple use of MEMS mirrors for some applications. The possible number of MEMS mirrors needed in some of the applications may approach 10 MEMS mirrors. This leads to an avalanche of units that will be required in the future.

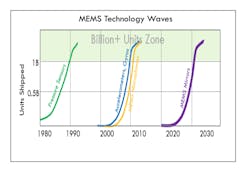

As is often the case with new technologies, there is a high probability for discovering additional unforeseen applications. We believe the next big wave in MEMS technology is MEMS mirrors, following in the footsteps of its well-established MEMS cousins pressure sensors, accelerometers, and microphones (see Fig. 4). We expect them to reach shipments of one billion units per year within the next 10 years.

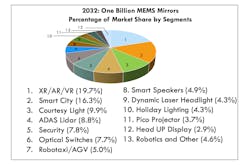

The makeup of one billion units by market segments is shown in Figure 5. The highest unit volumes are for automotive applications, where MEMS LiDAR in ADAS with Robotaxi, dynamic laser headlights, and heads-up display will take a market share of more than 20%. This will amount to hundreds of millions of units for automotive applications alone.

On the nonautomotive side, XR/AR/VR, combined with smart city and security applications, will be the leading applications for MEMS mirrors. Still, many other applications will amount to millions of units, which all together will bring MEMS mirrors to the level of one billion units per year.