GAVIN MARKILLIE, JOCHEN DEILE, and HOLGER SCHLUETER

In recent years, machine integrators and original equipment manufacturers (OEMs) have been keen to extend the range and variety of applications that are driven by low- to moderate-power, sealed CO2 lasers. Marking, scribing, and drilling of nonmetals have seen a steady growth, with users also moving into areas such as the cutting and welding of thin-gauge metals. In tandem with this increasing demand, manufacturers of sealed CO2 lasers have continually improved the machining performance of their products, while also reducing laser-head weight and size for ease of integration. The power level to which these designs can be extended is limited, however, and this has left a substantial requirement within the market for a compact and robust laser that can operate between 1 and 2 kW.

The choice of design for any industrial laser is based upon the maximum power level, reliability, and costs for investment and operation. For a CO2 laser, maximum power and efficiency are considered the two most important factors and are determined by the ability of the device to extract unwanted excess heat from the laser medium. Heat extraction can be performed by either diffusion to cooled walls or by flowing of the heated laser gas out of the discharge area. At power levels of 3 kW and up, the overall efficiency obtained using fast-axial-flow radial blowers and the ability to scale to powers in excess of 20 kW dictate that flowing of the gas is generally preferred. In contrast, at power levels below 3 kW, diffusion cooling becomes an attractive alternative—with overall efficiencies comparable to fast-axial-flow devices—with the added benefit that users can profit from a very simple no-flow structural design.

We have recently developed the TCF 1 CO2 laser to meet the market need for a laser working in the 1- to 2-kW power range. The laser operates with a diffusion-cooled discharge, but in a departure from other commercially available designs, the discharge shape is annular instead of planar. This approach results in a compact and robust device that is able to operate at power levels up to 2 kW, with a near-diffraction-limited beam.

Annular design

The concept of using concentric tubes instead of planar electrodes to create a radio frequency (RF)-excited discharge is not new. Many articles and patents describe various laser resonators that operate with an annular-shaped discharge.1 The clear benefits over plate-like designs are the increased discharge area for the same electrode footprint, the immense rigidity and robustness of tubular structures, and the possibility of the outer electrode acting as the main housing and vacuum chamber. However, to date the concept has enjoyed only limited commercial success because of the difficulty of maintaining a sufficiently concentric electrode gap—especially important for waveguide laser designs—and in the manufacture of annular resonator mirrors that allow both good beam qualities and efficient power extraction.

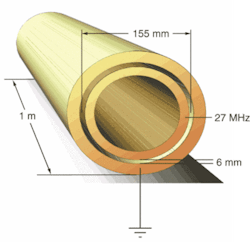

We addressed the annular problem on two separate fronts. With regard to concentricity, we utilized the increased discharge area of the annular design and opened the discharge gap to allow free-space propagation rather than waveguiding (see Fig. 1). This solution greatly reduces concentricity and alignment requirements and results in output powers similar to a planar waveguide with the same electrode footprint. Choosing a free-space gap also enables the discharge to be excited at 27 MHz, a frequency that does not require any special management of the lossy transmission line or additional RF feeds over the 1-m length of the electrodes. With respect to the annular resonator, we examined new mirror fabrication techniques that facilitate machining the mirrors in a manner that can be considered as the annular equivalent of the planar nonconfocal hybrid stable-unstable resonator.

The annular resonator

With any high-aspect-ratio discharge gap, one of the most challenging design issues is choosing a resonator that provides both good beam quality and efficient power extraction. The common approach with planar electrodes is to use a hybrid resonator based on simple cylindrical or spherical mirrors. The resonator is stable in the shorter transverse direction and unstable in the wider lateral direction. In general, this leads to an excellent transverse beam quality, while in the lateral direction a highly diffracted multimode operates, giving good gain sweep from the high-aspect-ratio gap. Post resonator filtering and formatting of the unstable beam results in a near-diffraction-limited beam with low ellipticity. Unfortunately, in annular lasers the fabrication of an equivalent resonator is not as straightforward, so much of the earlier work concentrated on stable-stable configurations.

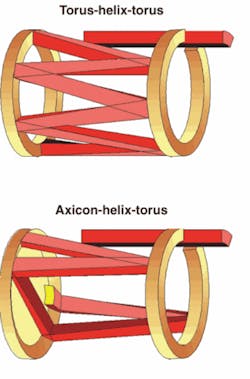

When generating an unstable beam in an annular discharge, it is useful to have one or both torus-shaped mirrors possess an azimuthal slope. This slope generates azimuthal beam inclination, corresponding to a single beam exiting the laser through an aperture in one of the mirrors. Without the azimuthal slope, a tilting of the mirrors is required to drive the beam, resulting in the extraction of two separate beams that makes post resonator filtering and formatting difficult.2 To machine an azimuthal slope onto our mirrors we use a Fast-Tool Servo.3 This is a piezoelectric device that adds a fast z-axis to a conventional diamond-turning machine. Precise movements of the tool are synchronized with the rotation of the optic on the lathe, allowing the machining of any desired shape with a nonrotational symmetric component of up to 35 µm in depth.The annular equivalent of the planar nonconfocal hybrid stable-unstable resonator is a simple torus, in conjunction with a torus mirror possessing an azimuthal slope and aperture; this later mirror we term a helix-torus.4 A stable transverse direction is formed with a radial-radius of curvature machined onto both mirrors (see Fig. 2, top). Unfortunately, this resonator is very sensitive to misalignment, generating large degrees of power loss, mode degradation, and beam steering. To combat these problems, we substitute the rear torus for an axicon or retroreflector (see Fig. 2, bottom).5 A retro-reflector is an optic having the special property that it produces a reflected beam path that is parallel to the incident direction, irrespective of the angle of incidence. With regard to the resonator, this means that "front" and "rear" mirrors essentially become one and the same structure; namely the helix torus. Misalignments of the helix-torus mirror now result in very low amounts of power loss, mode degradation, and beam steering. No effect is seen when tilting the axicon, even for values exceeding 1 mrad. The axicon also folds the resonator, thereby doubling its effective length. This reduces power fluctuations due to laser signature scanning to less than 1% and prevents line-transition hopping. Post resonator filtering and formatting of the beam results in a round beam with an overall k-number of ≥ 0.9.

Strength and durability

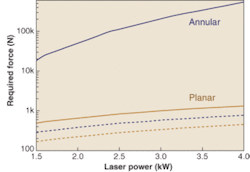

The results of a simple beam-bending calculation comparing annular and planer electrode designs demonstrate the structural rigidity of annular electrodes (see Fig. 3). With a 6-mm free-space gap, a 0.1-mm change in electrode separation has a marginal effect on both beam and laser power. In a 2-mm waveguide, the changes are more pronounced as the electrodes are an integral part of the optical structure. For the outer annular electrode, large forces are required to deform the structure by 0.1 mm, increasing substantially with output power (diameter). For the output powers shown, the ratio between the required deformation force and the force acting is at least one order of magnitude, indicating that the electrode structure can easily withstand accelerations in excess of 10 g without significant deformation. For the planar-waveguide structure the forces required to deform the electrodes are much smaller, indicating significant deformation will occur during initial machining or when the laser is moved. Sectioning of the electrode structure into smaller lengths is a possible way to combat this problem but at the expense of a more complex construction and additional optical loss.To test the rigidity of the annular laser and the effectiveness of the optical mountings for the internal mirrors and post-resonator beam-formatting optics, acceleration and lifetime trials were performed upon a completed laser head. During these trials, the laser was accelerated at 1 g through more than two million cycles. As expected we saw no measurable degradation in power or mode shape post-shaking. We performed both longitudinal and lateral shaking trials with similar results. In an additional trial, the laser was accelerated as described above while cutting sheet metal. Accelerations of up to 1 g showed no negative influence on the cut quality compared to that of a stationary mounted laser head.

The goal behind the development of the TCF 1 was a robust and compact diffusion-cooled laser capable of operating at power levels up to 2 kW with a near-diffraction-limited beam. The choice of an annular design resulted in a rugged, lightweight single-section electrode structure with a multifunctional outer electrode acting as the main structure and discharge housing. A combination of free-space propagation and a new hybrid stable-unstable resonator greatly reduced misalignment effects. The finished laser head can be accelerated in excess of 1 g, requires no periodic realignment, and has a greatly reduced requirement for servicing.

REFERENCES

- A. Lapucci, F. Rossetti and P. Burlamacchi, Optics Com. 111, 290, (1994).

- U. Habich, A. Bauer, P. Loosen and H. Plum, Proc. SPIE 1397, 383 (1990).

- Fraunhofer IPT; www.ipt.fhg.de.

- D. Ehrlichmann, Azimuthal unstable resonators and ring resonators for high-efficiency lasers, Dissert., RWTH, Aachen, Aachen, Shaker (1994).

- US Patent 6,285,703; EP 0,911,922.

Gavin Markillie, Jochen Deile, and Holger Schlueter are laser development engineers at Trumpf, 111 Hyde Rd., Farmington, CT 06032; e-mail: [email protected].