JASON ANAGNOSTIS and DAVID ROWE

For years, optical-system design was focused primarily on the use of simple spherical and cylindrical optical components, even though the use of more-complex aspheric, toroidal, diffractive, or hybrid optics could result in designs having superior performance. This dependence on refractive elements having constant radii stemmed from an inability to economically manufacture complex optics. Modern replication techniques that use light-cured photopolymers now provide a cost-effective way to produce high-quality complex transmission and reflection optical elements in high volume. The resolution of the replication process extends into the submicron regime, making possible the high-volume production of diffractive optics, including holographic optics.

Along with photopolymer replication, techniques for high-volume (greater than 1000 units) production of diffractive elements include diamond-turning, as well as other replication technologies such as injection-molding and hot-stamping. Each approach provides benefits for certain applications. When designing an optical system with complex optics, it is important for the designer to understand the different manufacturing processes available and the role that each process plays in the cost and performance of the optic being produced. The trade-offs when selecting a manufacturing approach include the desired optical component quality, component size, target price, operating environment, and spectral region of use.

Diffractive-optics manufacturing technologies

Injection-molding offers a low-cost way to produce complex optical components, including diffractive elements, in high volume. However, the resulting components are plastic—a considerable drawback when high-quality imaging optics or gratings are desired. Due to its high coefficient of thermal expansion, plastic cannot be used for high-numerical-aperture lenses or mirrors. The thermal limitations of plastic extend to most optics and gratings used in high-fidelity imaging applications (performing at or near the diffraction limit) intended for commercial or military environments. In addition, high-frequency gratings and microstructures pose a challenge for injection molding due to the melt-flow characteristics of plastic.

Newly developed injection-molding technology is beginning to cross over from research into industry. The technology focuses on the replication of gratings through development of significantly more-precise machines and molds and the incorporation of new techniques to enhance the flow of the material. Injection-molding is the method of choice when high-volume production of optical components, from simple spheres to complex hybrid diffractive-aspheric components, is required, as long as the end product does not require high-quality imaging characteristics. Examples of components produced by this method include disposable camera optics and ophthalmic lenses.

Hot-embossing is another method of high-volume manufacturing of micro-optics and gratings.1 This process is similar to injection-molding in that it uses a press into which the desired optical mold pattern is fabricated. But instead of flowing heated plastic into the mold, preformed plastic sheets are fed into the press, and the heated mold embosses the plastic sheet with the mold pattern.2 The quality of the optic is limited by the properties of the substrate and the accuracy by which reproduction of the optical mold can be achieved. As with injection-molding, because the final component is formed in plastic, thermal-expansion issues and the operating wavelength range of the optic must be considered.

Examples of components produced by this method are nonimaging lenslets used in light-controlling optics, gratings for nonimaging medium-precision metrology encoder scales, retroreflective tape, and holograms on credit cards. When low- to mid-quality optics are required in high volumes and plastic is an acceptable substrate material, either injection-molding or hot-embossing will likely be the most attractive approach

Diamond-turning machines also can create diffractive optics, although of coarse pitch. The machines, which are basically precision lathes with air-bearing spindles and stiff precision hydrostatic ways, also can produce complex mirrors and lenses with lambda/4 or better surface figure. Diamond-turning has proven very useful for the production of optics for the infrared (IR) and for some visible applications. The cutting process, however, creates nanometer-depth grating patterns on the surface of the optic, which at shorter wavelengths produce unwanted diffraction.

Diamond-turning can be used to cut optical surfaces directly into nonferrous metals such as aluminum and nickel and most plastics, making it attractive for volume production of small optics. On the other hand, due to the cutting rates of diamond-turned optics, which can be as slow as 1 mm/min, volume production of larger optics is not economical. In addition to diffractive optical elements, examples of diamond-turned optics include mirrors and lenses for IR wavelengths, Fresnel lenses, and a majority of the optical molds used for injection molding. Diamond-turning is best suited for IR and other niche applications.

Light-cured photopolymers

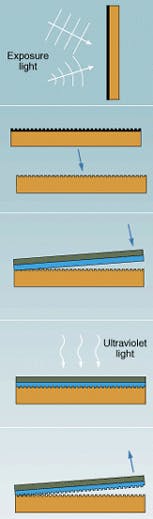

Replication using light-cured photopolymers provides a cost-effective way to produce high-quality complex transmission and reflection optical elements in high volume (see Fig. 1). Unlike epoxy replication, which can take many hours to produce a part, photopolymer replication is truly high-speed—in many cases rivaling injection-molding cycle times.

The photopolymer replication process consists of taking a high-quality mold and replicating its surface onto a low-quality substrate by using the photopolymer as an interface layer. The assembly is exposed to light that cures the photopolymer in a matter of seconds. The mold is then removed, with the photopolymer preferentially adhering to the substrate. The replicated part can then be coated with either a high-reflection or antireflection coating as necessary to produce the final optic. One drawback of photopolymer replication is that either the mold or the substrate must transmit light to facilitate the curing. In most cases, however, this does not pose a problem, because a glass submaster can always be generated from the master by replication, which can then be used to replicate the final optic.

The difference between photopolymer replication and injection-molding or hot-embossing is the ability to produce high-quality optics that do not possess the thermal constraints of plastics. This is due in part to the fact that the replica consists, in most cases, of only a thin (less than 20 µm) layer molded onto a rigid substrate. Because the replica layer is thin compared to the substrate, it expands and contracts with the substrate. For example, if the base substrate is glass, the replicated optic performs as a glass lens would.

Another important benefit is the ability to replicate almost any type of microstructure in high volume. This process is ideal for replicating high-aspect-ratio holographically recorded gratings (see Fig. 2). The minimum feature size that can be replicated has yet to be determined; however, microstructures with 200-nm features have been replicated for multiple applications.Application of photopolymer replication

A manufacturer of high-precision positioning devices—MicroE (Natick, MA)—has patented a diffraction-based encoder technology and incorporated it into its devices. The high-resolution capability of these devices has made them popular tools for the metrology and hard-drive industries.

Originally, each encoder grating was produced either in photoresist or by using chrome-on-glass masters. When used for production, the drawbacks to the photoresist method included variation in part-to-part repeatability and lack of durability of photoresist. Furthermore, for either approach, the production cost was too high to make high-volume production feasible. To enter higher-volume markets, it was clear that a different manufacturing method was necessary to reduce cost and increase throughput. Today, many of the mid- to high-volume encoder gratings used in the MicroE devices are created by photopolymer replication, solving these production problems.

REFERENCES

- M. Hecke, W. Bacher, and K. D Müller, Microsystem Technologies 4, 122 (1998).

- M. T. Gale, Microelectronic Engineering 34, 321 (1997).

Jason Anagnostis is a senior research chemist and David Rowe is president of Holographix, 577 Main St., Ste 6, Hudson, MA 01749; e-mail: Hgraphix@ hgraphix.com.