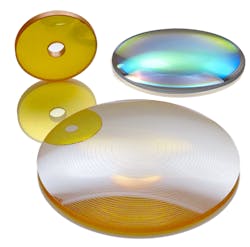

New aspheric lenses fabricated from CaF2, ZnSe, and ZnS substrates feature surface accuracies of ~λ/4 at 633 nm to achieve small focused spot sizes, surface roughness of 40 to 50 Å rms for minimal scatter and loss, and multilayer thin-film coatings. The coatings, which have a densified structure, offer multispectral performance and high laser damage threshold.

REO

Boulder, CO

www.reoinc.com

-----

PRESS RELEASE

REO Introduces High Performance Aspheres for Visible and Infrared

REO, a leading manufacturer of high volume precision optical solutions, has introduced a new range of high performance aspheric lenses fabricated from CaF2, ZnSe and ZnS substrates. These lenses offer a unique combination of benefits for demanding applications that require broadband or multispectral operation from the visible through the infrared, such as military rangefinding and target designation. These advantages include high surface accuracy (~?/4 at 633 nm) to achieve small focused spot sizes, low surface roughness (40 to 50 Å rms) for minimal scatter and loss, and sophisticated, multi-layer thin film coatings. In particular, these coatings offer multispectral performance and high laser damage threshold, and are produced with a densified structure to yield exceptional environmental stability. And because these advantages can be maintained even with unusually thin lens profiles, these new aspheres can deliver important weight advantages for man portable, field and airborne applications.

REO’s aspheres are produced utilizing single point diamond turning technology which enables highly accurate reproduction of virtually any rotationally symmetric aspheric shape. In addition, REO can also employ diamond turning to create a surface diffractive phase profile, enabling more sophisticated functionality, such as achromatization of single element lenses. REO also has extensive capabilities for machining lenses to yield both centered and off-center through holes or to achieve shapes other than circular.

REO fabricates and coats these aspheric lenses in high volume on a custom basis. Small prototype batches can be ordered for evaluation and development purposes. Typical diameters for these components range from 0.25" to 8", depending upon substrate material.

Subscribe now to Laser Focus World magazine; it's free!