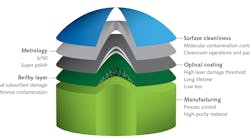

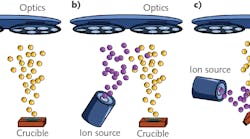

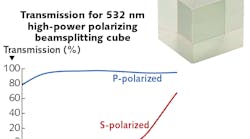

Optimax implements an engineered solutions approach to help our customers achieve breakthroughs in the aerospace, defense, semiconductor, research, and medical industries. Optimax has a wide range of capabilities to support your programs, including aspheres, cylinders, freeforms, prisms, spheres, and advanced e-beam, APS, IAD, and IBS coatings.

Optimax helps its customers prove that great people can do great things with the right technology and support.

We leverage our optics manufacturing technology for programs that benefit mankind and projects that defend our freedom. Our know-how, innovation, and speed enable quicker production of high-precision optics to meet emerging market needs. Some of the most sophisticated programs in the world trust Optimax to produce the most complex optics reliably.

Since Optimax was founded in 1991, optics have been behind enormous progress in technologies as diverse as fiber optic telecommunications, solid-state lighting, digital photography, displays, and diagnostic medicine. We have worked key programs in aerospace, government research and defense, and our customers’ successes have fueled our growth.