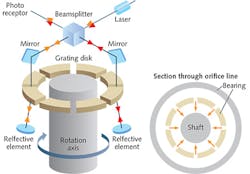

The trends of miniaturization and high-speed performance in today's optoelectronics industry place demands on a product's thermal and optical properties. For example, digital rotary scanners that focus laser light onto a rotary drum to create a reflective full-sized copy of a drawing contain optics at one end of the spinning axis of the scanner. To prevent vibration, the metal shaft at the center of the rotary scanner is cushioned by an air bearing that runs at high speed and can transfer heat to the shaft that in turn can transfer to the optics and negatively affect focusing precision.

Because these rotary scanners have little room for active thermal control and would otherwise require an optical redesign to function with a high heat load, rotary scanner manufacturers have discovered that a MACOR mica glass-ceramic material from Corning (Corning, NY) can be inserted between the rotating shaft and the optics to provide passive thermal and electrical insulation. It can be machined using conventional metalworking tools with no post-firing requirements, and is stable in high-temperature environments (continuous at 800°C up to 1000°C peak) with zero porosity and outgassing. A radiation-resistant, passive thermal and electrical insulator with low thermal conductivity, MACOR can be machined to a surface finish of less than 0.5 μm and polished to a smoothness of 0.013 μm. Contact Franck de Lorgeril at [email protected].