Compactness in any form of instrumentation is appreciated by users who have to move that instrumentation around and fit it into small places. Engineers at Ophir, which is part of MKS Instruments (Andover, MA), have gone quite far down this route by creating a self-contained, battery-powered laser power meter for high-power lasers that is a mere 70 × 70 × 79 mm in size. Called the Ariel, the dustproof and water-resistant (rated to IP 62) device can measure the power of laser beams with powers from 200 mW to 8 kW, with up to 20-s-long measurements possible for 500 W beams and shorter measurements necessary for beams up to 8 kW; it delivers measurements within 3 s. The Ariel has a thermal capacity of 14 kJ, which means that it can measure several consecutive pulses with an accumulated energy of 14 kJ before it needs to cool down. According to Reuven Silverman, General Manager at Ophir Photonics, 14 kJ of rapidly applied laser energy heats the device to about 60°C, after which it is left to cool for a short period of time before further measurements.

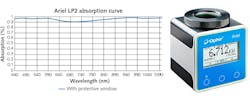

With newer industrial laser applications in mind, Ophir engineers gave the power-absorbing surface of the Ariel power meter an LP2 coating that can be used for blue and green wavelengths of 440 to 550 nm, as well as standard infrared (IR) wavelengths of 900 to 1100 nm, 2.94 μm, and 10.6 μm. (Recently developed blue and green lasers, now commercialized, are finding use for copper welding of automotive batteries, as well as electronics.) Communication options include Bluetooth and USB, and the Ariel comes with a diffuser that can be mounted for use with small-diameter beams. Applications include metal-based additive manufacturing, metal cutting, welding (including copper welding), and medical-device fabrication.

“Accurately measuring laser power is critical for ensuring product quality, repeatability of operations, and process validation in manufacturing operations,” notes Silverman. “Lasers change over time—they heat up, they degrade.” He gives an example of how some shops may compensate for a gradual loss in laser power by overwelding; however, overwelds are heavier, and applications such as automobile manufacturing can’t tolerate extra weight. Silverman adds that he knows of a major auto manufacturer who measures its laser powers “between every weld.” See ophiropt.com/photonics.