ERIC TAKEUCHI, KYLE THOMAS, and TIMOTHY DAY

Extraordinary progress has been made in advancing the performance and manufacturability of quantum-cascade (QC) materials. This progress has driven many to adopt and develop this technology for a broad array of applications in the mid-infrared. At the same time, there has been a great deal of innovation in design and manufacture of miniaturized external-cavity lasers (ECLs). By integrating QC gain media into ECL geometries to form external-cavity quantum-cascade lasers (ECqcLs), the tremendous value of these technologies is being realized. Increased power, efficiency, and tuning range are now possible as a function of this combination.

While the combination of QC and ECL into ECqcL may appear to be a mere reorganization of letters, it is much more than that. It is important to note that in external-cavity geometries, the QC material serves only as the gain medium around which external cavities can be built; this change in approach has the inherent ability to unleash all that QC technology has to offer.

QC technology has arrived

Historically, researchers primarily used QC technology in the lab for detection and illumination in the mid-infrared. Over the past few years, however, the epitaxial growth of QC gain media has moved from research and university laboratories into commercial manufacturing foundries. In many cases, these foundries have leveraged their production experience, processes, and capacity in traditional III-V semiconductor materials (for example, gallium arsenide and indium phosphide) to yield high-quality QC chips with excellent performance. Quantum-cascade wafers can now be grown using industry-preferred metalorganic chemical-vapor-deposition (MOCVD) techniques, which offer several advantages when compared to molecular-beam epitaxy (MBE) methods.1 For example, the faster growth rates enable volume production processes to be developed quickly, providing significant yield and cost improvements.

Similarly, the performance of QC gain media has advanced considerably. Ultrabroadband gain from a single QC die has been demonstrated from 5 to 8 µm (750 wavenumbers).2 Through comprehensive waveguide and thermal modeling, QC structures optimized for continuous-wave operation with high-power, high-efficiency Fabry-Perot lasers (simple cleaved facets) have also been demonstrated with single-facet output power greater than 1.3 W at room temperature.3, 4

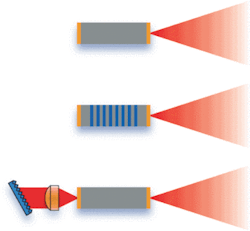

Given the recent maturation of QC technology at the die level, various laser types can now be considered (see Fig. 1). The simplest geometry is the Fabry-Perot laser (FP-QCL). Here, the cleaved facets provide feedback for lasing, although dielectric coatings are often applied to optimize output. A second geometry involves fabrication of a distributed-feedback grating directly on the QC die. This geometry (DFB-QCL) provides narrower spectral emission but much lower power as compared to the FP-QCL geometry. It also provides for limited tuning of the wavelength through extreme temperature tuning of the device (typically 10 to 20 cm-1 with slow temperature tuning or 2 to 3 cm-1 with faster joule heating with injection current).

A third geometry integrates the QC die into an external cavity (ECqcL).5, 6 This also provides narrow spectral emission, but also allows for rapid tuning (faster than 10 ms) across the entire gain bandwidth of the QC die (hundreds of cm-1). Because the ECqcL geometry can be made with low-loss components, it can maintain high efficiency to enable portable battery operation.

Principal components of an ECqcL

Ultimately, a QC semiconductor chip serves only as the gain medium around which laser cavities must be designed. Die attach and thermal management, dielectric coatings, micro-optics, wavelength control, electronic drive, and packaging all play critical roles in reliably providing the benefits mentioned.

Appropriate selection of solder and heat-sink materials is critical to QC die attach. Furthermore, long-term reliability relies heavily on the correct implementation of these processes, which have now been implemented for various QC designs, including buried heterostructures and ridge waveguides, and for epi-up and epi-down mounting configurations.

High-performance dielectric coatings must also be applied to optimize output. Reflectivity of less than 0.001 has now been achieved on ECqcL devices. These coatings provide broadband performance (hundreds of wavenumbers) while maintaining fidelity over high heat and stress loads.

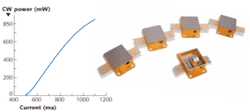

Combined with efficient drive electronics, ECqcLs can now be driven with conventional battery sources. Compact “thermal laser pointers” with outputs in excess of 50 mW can run for several hours from a simple AA battery pack (on a single charge) and without requiring temperature control (in other words, uncooled). Even when integrated into turnkey sensors, real-time data can be provided with greater than four hours of continuous run time from a single battery charge.

Because of the highly diverging output that is characteristic of most semiconductor lasers, optics with a high numerical aperture (NA) are typically required to provide near-diffraction-limited performance. In a typical example, the far-field intensity distribution from an ECqcL collimated using high-NA (greater than 0.8) micro-optics shows a beam quality M2 of better than 1.2.

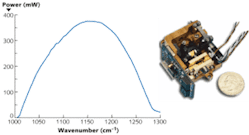

Perhaps the most compelling attribute of QC technology is the ability to access a broad range of wavelengths from a single device and simultaneously maintain excellent spectral purity.7 Single-mode tuning ranges approaching 300 wavenumbers are now achievable from commercially available ECqcL products (see Fig. 2).8 Simultaneously, individual wavelengths can be tuned with an accuracy of better than 1 in 104. Tuning across the entire gain bandwidth can also be achieved in less than 10 ms while still maintaining narrowband emission.Applications proliferate

External-cavity QCL technology is being considered for many applications across multiple markets. The medical-diagnostics community is exploring portable, wearable sensors for noninvasively detecting glucose. Similar ECqcL-based sensors are being fitted to standardized breath-monitoring apparatus and used for noninvasive medical diagnostics.9 This technology is also being used in the field of personal safety to ensure that workers in an industrial setting can continually monitor their exposure levels to toxic gases. Real-time measurements of nitrogen oxides, sulfur oxides, carbon dioxide, carbon monoxide, ammonia, and other combustion gases are being used to minimize fuel consumption and stack emissions in marine and industrial environments.

All of these sensors can be integrated with wireless capability, enabling real-time data monitoring and storage at a central server, which can be empowered to initiate response actions. Similarly, environmental-monitoring networks can be established to provide wide-area or local-area coverage to determine air-quality trends over time and space (see Fig. 4).10ECqcL technology is also being used for illumination applications. “Thermal laser pointers” are being tested by members of the defense community; when used in concert with new, low-cost thermal-imaging cameras, these devices are ideal as “flashlights” designed to enhance sensitivity in fugitive gas-emissions detection, and as sources for standoff applications such as detection and identification of explosives.

High-power ECqcLs have been scaled into multiwatt systems. Their size, weight, and power consumption benefits make them ideal candidates for applications such as infrared countermeasures for military and commercial aircraft protection, as well as applications in active infrared imaging and for long-distance standoff detection.

References

- Z. Liu et al., IEEE Phot. Tech. Lett. 18(12) (2006).

- C. Gmachl et al., Nature 415, p. 883 (2002).

- S. Howard et al., IEEE Sel. Top. Quant. Elect. 13(5) p. 1054 (2007).

- Y. Bai et al., Appl. Phys. Lett. 92, p. 101105-1 (2008).

- G. Wysocki et al., Appl. Phys. B 92, p.305 (2008).

- T. Day et al., “Miniaturized external-cavity quantum-cascade lasers for broad tunability in the mid-infrared,” CLEO and 2006 QELS (May 2006).

- R. Maulini et al., Appl. Phys. Lett. 88, p. 201113, 2006.

- www.daylightsolutions.com.

- T. Risby and S. Solga, Appl. Phys. B 85, p. 421 (2006).

- MIRTHE (Mid-InfraRed Technologies for the Health and Environment), an NSF Engineering Research Center headquartered at Princeton University (www.mirthecenter.org).

Eric Takeuchi is director of business development, Kyle Thomas is vice president of sales and marketing, and Timothy Day is CEO and CTO of Daylight Solutions, 13029 Danielson St., Suite 130, Poway, CA 92064; e-mail: [email protected]; www.daylightsolutions.com.