For the first time, researchers from Belgium succeeded in integrating a pinned photodiode structure in thin-film image sensors. With the addition of a pinned-photogate and a transfer gate, the superior absorption qualities of thin-film imagers—beyond 1 µm wavelength—can finally be exploited to unlock the potential of sensing light beyond the visible in a cost-efficient way. This novel approach opens doors to diverse applications, from autonomous driving to environmental monitoring.

Overcoming silicon’s limits

Silicon-based imagers excel at capturing visible light. But for longer wavelengths such as shortwave-infrared (SWIR or IR), offering applications ranging from a camera supporting the sorting of household waste to autonomous vehicles 'seeing' through smoke or fog, alternative semiconductors are necessary.

While III-V materials are addressing this need, high manufacturing costs limit their widespread use, crucial for large-scale rollout within the automotive domain. Enter the promising alternative of thin-film-based absorbers, including organic compounds or quantum dots. These materials feature superior absorption characteristics and can be easily integrated with conventional complementary metal-oxide semiconductor (CMOS) readout circuits.

Breaking barriers with pinned photodiode structures

Nonetheless, the adoption of IR sensors using thin-film absorbers faces challenges, primarily related to low signal-to-noise ratios (SNRs) leading to poor image quality. Recent developments have overcome these issues for the first time—not by changing the choice of materials, but by building upon the rich history of pinned photodiode (PPD) structures in silicon-CMOS image sensors, dating back to the 1980s.

The PPD structure, with its additional transistor gate and specialized photodetector structure, significantly reduces noise, thereby making it a dominant force in the consumer market for silicon-based image sensors. It allows reset operation of the transistor without kTC noise or the effect of the previous frame to provide a kind of ”super-switch” by which charges can be completely drained. But incorporating a PPD inside thin-film-based sensors has never been possible because of the complexity of integrating two different semiconductor systems.

A leap in image sensor architecture

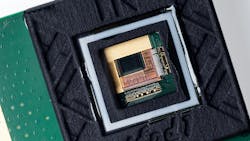

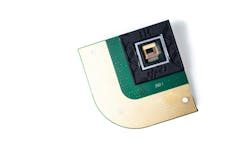

In a recent Nature Electronics paper, we presented the successful incorporation of a PPD structure into the readout circuitry of a thin-film pixel (see Figs. 1 and 2). This proof-of-concept leverages imec’s in-house expertise in both thin-film materials and photodiodes to surpass current thin-film pixel architectural limitations. While the individual components of this pixel have been around for a long time and have proven their worth in other applications, our proof-of-concept demonstrates their collective value and versatility in sensing light beyond visible.

For the photogate transistor, we selected indium-gallium-zinc-oxide (IGZO), due to its compatibility with thin-film photodiodes and because it can be integrated into silicon readout circuits. Such transistors have already demonstrated their effectiveness in various applications, including memory technologies.

Next, this IGZO transistor was monolithically hybridized with a thin-film organic photodiode directly on top of the CMOS readout circuitry. This wafer-level post-processing enables scalable and affordable manufacturing, which paves the way for large-scale applications.

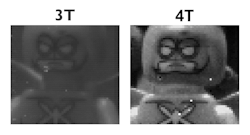

The resulting 4T SWIR imager showed a low read-out noise of 6.1 e-, compared to >100 e- for the conventional 3T reference sensor (see Fig. 3). With such a reduction in noise, higher SNRs can be achieved. As a result, images can be captured with more accuracy and detail. Moreover, as fewer photons are necessary to induce signals, even weak signals can be converted into images.

Advancements in linearity: The key to precision

In follow-up research, our team showed that the introduction of this PPD pixel structure also resulted in a more linear response—a measure for the accuracy of image reproduction. And the photodiode bias was fixed, which effectively reduces dark current (by 72%) and increases the linearity (error reduction of 59%) for organic thin-film photodiode-based image sensors. Adding a photogate ensured a more faithful representation of the captured scene, which is critical for applications where accurate image reproduction is paramount.

Beyond this, the initial pixel was designed to maximize charge to voltage conversion gain—with a resulting limited floating diffusion capacitance—and is not able to demonstrate high full well capacity. A second-generation pixel structure did enable a high full well capacity exceeding 1 Mega electrons of the proposed pixel (with a pitch of 5 µm). This ensures a dynamic range of >100 dB, compared to the 82 dB of the 3T pixel, and represents the ability of this high SNR pixel to capture a wide range of light intensities—from the darkest to the brightest.

Accelerating thin-film-based image sensor deployment

This pixel architecture offers opportunities for other promising thin-film photodiodes beyond organic, including perovskite absorbers or quantum dots. Since the photodiode is separated from the readout circuit and integrated via post-processing, the absorption materials we use do not need to undergo stringent optimization before integration with the readout circuitry.

This novel 4T pixel architecture can accelerate the deployment of monolithic thin-film-based image sensors. The benefits of our architecture can serve as a catalyst for novel applications that are either not covered or inadequately addressed by silicon imagers.

FURTHER READING

J. Lee et al., Nat. Electron., 6, 590–598 (2023); https://doi.org/10.1038/s41928-023-01016-9.

J. H. Kim et al., Sensors, 23, 8803 (2023); https://doi.org/10.3390/s23218803.

M. Jin et al., IEEE Electr. Device L., 44, 12, 2007–2010 (Dec. 2023); https://doi.org/10.1109/led.2023.3325830.