Master Bond LED415DC90 is a one component adhesive system that cures rapidly upon exposure to a 405 nm wavelength LED light source without any oxygen inhibition. The rate of cure depends upon the intensity of the light source, the thickness of the adhesive layer and the distance from the light to the adhesive. This no-mix system requires a post cure with heat, and adheres well to both similar and dissimilar substrates.

“Conventional light curing adhesives do not allow light penetration beyond 1 mm. LED415DC90’s key distinguishing factor is its ability to partially cure or fixture up to 6 mm deep or in cross sections under LED light at the right intensity,” says Rohit Ramnath, Senior Product Engineer. “That enables a unique practical feature of this product: fixturing of components which are opaque. The mechanism in which this occurs is by allowing the light to penetrate through the adhesive from the sides and not needing light to be exposed throughout the entire areas. It must be noted that post curing with heat at about 95°C for 30-60 minutes is critical for enhancing strength and overall performance.”

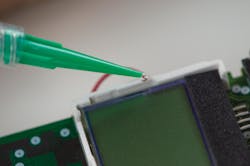

LED415DC90 has a thixotropic index of 5.53 at room temperature. It has a good physical strength profile with a tensile strength of 5,500-6,500 psi, a tensile modulus of 450,000-550,000 psi, and lap shear strength for Aluminum to Aluminum of more than 1,000 psi. This rigid system cures with a hardness of around 85-90 Shore D and elongation of 1-3% at 75°F. Serviceable from -80°F to +350°F, it is electrically non-conductive with a volume resistivity greater than 1014 ohm-cm. It is available in EFD® syringes, ½ pint, pint and quart containers.