Master Bond UV22DC80-1Med is a single component, nanosilica filled compound featuring a UV and heat curing mechanism. Not only does it pass USP Class VI tests for biocompatibility, but it also meets ISO 10993-5 for cytotoxicity, making it ideal for many applications in the medical device industry.

As a nanosilica filled system, UV22DC80-1Med offers low shrinkage upon cure, excellent abrasion resistance and dimensional stability with a low coefficient of thermal expansion of 30-35 x 10-6 inch/inch/°C. It is a reliable electrical insulator with volume resistivity of more than 1014 ohm-cm and dielectric constant of 3.85 at 60 Hz. UV22DC80-1Med is optically clear with a refractive index of 1.52.

The UV curing process for UV22DC80-1Med takes only 10-30 seconds at a 365nm wavelength and 10-40 mW/cm2of UV output. The heat curing process can be initiated at 80°C, making it highly desirable in applications involving heat sensitive components. Optional post curing at 125-150°C for 15-30 minutes will increase the glass transition temperature to over 125°C. This system is not oxygen inhibited.

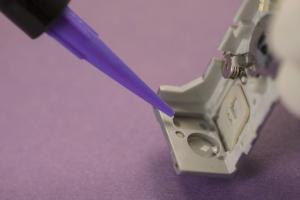

UV22DC80-1Med has a low viscosity of 500-3,500 cps at 75°F (~ 23°C). It bonds well to a variety of substrates including metals, glass, ceramics and most plastics. This compound has very good resistance to various sterilization methods including autoclaving and many chemical sterilants. It is available for use in 30 cc EFD syringes, ½ pint, pint, and quart containers.