Half a century after development of the first low-loss silica fibers, the attenuation of hollow-core silica fibers has been pushed down to only twice that of today’s best solid-core single-mode fibers. In his March 10, 2020 opening plenary talk at the 2020 Optical Fiber Communications Conference (OFC; San Diego, CA), Sir David Payne, director of the Optoelectronics Research Center at the University of Southampton (Southampton, England), announced fabrication of a hollow-core fiber with loss of 0.28 dB/km. “Is there a future for silica as an optical material?” he mused.

Two days later, Eric Numkam Fokoua of Southampton prefaced his description of the record low-loss hollow-core fiber at the postdeadline session by observing, “this is a very unusual conference.” Payne had spoken on a stage in San Diego. Fokoua gave his presentation from across the Atlantic, and fiber-optic cables relayed it to OFC, which distributed it to virtual conference-goers around the world who, like Fokoua and myself, had been kept home by the fast-spreading Coronavirus.

Payne, who began working on fiber optics in 1967 and is best known for inventing the erbium-doped fiber amplifier (EDFA), has been part of a group working on hollow-core fibers for the past several years. At the European Conference on Optical Communications (ECOC) in 2019 held in Dublin, Ireland, Thomas Bradley of Southampton reported a record-low attenuation of 0.65 dB/km across the full C and L telecommunication bands. In just six months, that attenuation has been cut by more than 50%.

Latency reduced in vacuum by 30%

“Vacuum is the very best optical material we know, but we need guidance,” Payne said. Hollow-core microstructured fibers could provide that guidance, confining light within a central hole instead of a solid core. Light travels fastest in vacuum, reducing latency by 30% compared to transmission through glass. He also listed other ways vacuum aids optical signal transmission: “incredibly low nonlinearity,” low dispersion across a wide range of wavelengths, transparency across a very broad spectrum, and resistance to damage from high optical power and from nuclear radiation.

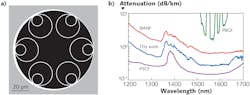

The new hollow-core fiber is of the same type that Southampton described at ECOC in 2019: nested antiresonant nodeless fiber (NANF). The improvements in performance came from refinements of the design (see figure). Fokoua said they redesigned the internal structure that confines light to reduce the core size to 34.5 µm, an advantage because it reduced microbending losses. Process refinements more than doubled the maximum lengths of drawn fibers to 2.8 km. After simulations showed that the central LP01 mode had the lowest attenuation of 0.27 dB/km, they reduced the fraction of light in the LP11 mode, where attenuation was 10 to 12 dB/km. That let them keep loss no more than 0.28 dB/km between 1510 and 1600 nm, and lower than 0.3 dB/km from 1500 to 1640 nm. “Leakage alone accounts for 0.26 dB/km in this fiber,” Fokoua said, suggesting room remains for reduction. “We’re tantalizingly close to beating silica.”

The postdeadline session also heard a report of record transmission distance through 772 of hollow-core fiber by Antonio Nespola of LINKS Foundation (Torino, Italy), part of the Southampton team. They were able to detect a 32 Gbaud signal sent in the center one of 61 channels in the C band that had looped a hundred times through 7.72 km of hollow-core fiber formed by splicing 4.34 and 3.38 km lengths. That’s more than twice the previous record reported last year at ECOC 2019. At the current rate of improvement, Nespola and colleges wrote, the potential of NANF fiber to achieved both low loss and ultralow nonlinearity across very wide bandwidths could make it a candidate for increasing the throughput of fibers many-fold in the next generation of higher-capacity fibers.

Deployable hollow-core-fiber cable

That record transmission was over spooled fiber, but hollow-core fibers must be cabled for practical applications. At the postdeadline session, Benyuan Zhu of OFS Laboratories (Somerset, NJ) and colleagues reported error-free transmission through what they call “the first field-deployable hollow-core fiber cable.” Hollow-core fibers are structurally complex and cabling can introduce problems including micro- and macrobending loss, polarization mode dispersion, and multipath interference in few-mode fibers. OFS developed a loose-tube cable for direct burial or underground duct installation that controls those problems and can operate at temperatures from -40° to 80°C.

Instead of aiming at the usual goal of highest possible bandwidth, OFS optimized their demonstration for applications such as high-frequency trading willing to pay a steep premium for low latency. Microseconds mean money in that market, and hollow-core fiber cuts 1.54 µs/km of distance. Low latency matters more than high data volume, so OFS transmitted nonreturn signals at 10 Gbit/s on 33 DWDM channels through 3.1 km of cabled hollow-core fiber to a direct-detection receiver. Forward error correction and digital signal processing would have allowed coherent transmission at much higher data rates, but would have added 5.6 to 9 µs in latency. Zhu reported the low-speed transmission kept bit error rates below 10-15.

Progress in hollow-core fibers also is expanding interest in wavelengths outside the traditional 1550 nm band. The possibility of low-loss transmission in the 2 µm band has increased interest in thulium-doped fiber amplifiers and coherent generation and transmission in that band. Silicon modulators have been developed for the 2 µm band. In the postdeadline session, Yu Wang of Southampton reported a bismuth-doped fiber amplifier with gain of more than 20 dB from 1345 to 1460 dB, a record bandwidth for bismuth.

In answer to Payne’s question, silica will remain an important optical material in hollow-core fibers because it provides the cladding and internal structures. At OFC, he also mentioned a new optical application for silica, as an “eternal memory” created by writing nanostructures with femtosecond pulses.