CALVIN MILLER, TOM LI, JEFF MILLER, FAYE BAO, and KEVIN HSU

Fiber Bragg gratings (FBGs) are an enabling technology in the telecommunications industry where they are used for dense wavelength division demultiplexing, dispersion compensation, laser stabilization, and erbium-doped amplifier gain flattening—all in the 1550-nm wavelength region. When used as optical fiber sensors, FBGs also offer many advantages, the two most important being direct transformation of the sensed parameter to an optical wavelength and the potential for highly multiplexed operation.

Fiber Bragg gratings have been studied as optical sensors for a variety of mechanical sensing applications, including condition monitoring of civil structures such as highways, bridges, buildings, and dams; smart manufacturing and nondestructive testing of materials such as composites and laminates; remote-sensing applications in oil wells, power cables, pipelines, and space stations; smart structures such as airplane wings, ship hulls, buildings, and sports equipment; and traditional strain, pressure, and temperature sensing. The main advantage of FBGs for mechanical sensing is that they perform a direct transformation of the sensed parameter to a shift in reflected wavelength, independent of light levels, connector or fiber losses, or other FBGs operating at different wavelengths.

Compared to resistive foil strain gauges, FBGs have a narrow bandwidth and can operate over a broad wavelength range that can be highly multiplexed, that is, allowing many of them to be used on a single fiber. Such gratings are small enough to be embedded or laminated. Because they are totally passive, there is no resistive heating. They are also nonconductive, thus immune to electromagnetic interference. Because they are made from glass, they are more environmentally stable than copper. Also, with low fiber loss at 1550 nm, FBGs can be used for remote sensing. Finally, FBGs are potentially very low cost because of their simplicity and their use in high-volume telecommunications applications.

Measuring reflected wavelengths

To realize the potential of FBGs for mechanical sensing, Micron Optics has developed a multiwavelength-referenced FBG interrogation system for rapid, accurate measurement of multiple FBG-reflected wavelengths. The interrogation system was developed originally for military applications, down-hole oil exploration, high-pressure steam pipe monitoring, and gas detection; some other applications under development or already underway are space vehicle health monitoring, smart manufacturing, and bridge, highway, and tunnel monitoring.

In the basic—nonreferenced—interrogation system, a 1550-nm-output light-emitting diode (LED) illuminates, through a coupler, a connected series of FBGs, each of which reflects a different wavelength of light. These wavelengths shift slightly depending on the strain applied to each FBG sensor. A single-fiber Fabry-Perot (FFP) tunable filter scans the entire wavelength range of the FBGs—typically 40 nm—and the filter output is electrically detected, differentiated, and zero-crossing-processed to achieve subpicometer wavelength measurement resolution. This measurement technique has been used by investigators for several years to measure short-term dynamic strain at frequencies up to a few hundred hertz.1 Extremely high wavelength resolution of less than 1 picometer (pm) can be achieved at 250 Hz with this approach, and short-term repeatability is excellent. This technique has also demonstrated wavelength multiplexing capacity.

Major problems with this nonreferenced FBG interrogation setup include nonlinear wavelength response due to FFP tunable filter optics and the mechanical actuator (PZT), drift and instability from thermal coefficients of FFP tunable filters and other components, and the overall wavelength measurement inaccuracy of several nanometers (several thousand times the resolution). By subtracting the wavelength shifts of a reference temperature-sensing FBG and maintaining stable operating conditions, some of the effects of the above problems can be minimized.2 Moreover, suitable stability has been achieved to measure strain changes over periods as long as 40 days.3

Fixed Fabry-Perot reference

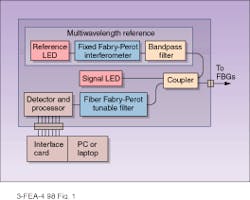

Micron Optics has included a multiwavelength reference in its FBG interrogation system to solve these linearity, stability, and accuracy problems (see Fig. 1). A second LED, a bandpass filter, and a fixed Fabry-Perot interferometer are connected to generate this reference. The fixed Fabry-Perot interferometer in combination with a reference FBG is mounted on a thermoelectric heater/ cooler, and both are kept at a constant temperature (about 45°C). In this configuration the reference FBG serves to uniquely identify the multiple Fabry-Perot orders of the fixed Fabry-Perot interferometer.

Intrinsic to the fixed Fabry-Perot interferometer are uniformly spaced passbands (Fabry-Perot orders, M) with better than 1-pm spacing uniformity that can be easily fabricated with approximately 1 nm between Fabry-Perot orders. With temperature stabilization and accurate reference calibration, the fixed Fabry-Perot interferometer constitutes an excellent multiple-wavelength reference. By subdividing the 5000-GHz (40-nm) optical spectrum into 1-nm increments, accuracy, stability, and linearity of the FFP tunable filter on the order of 1 pm can be achieved.

The proper fixed Fabry-Perot interferometer passband, M, must be identified or a gross error of approximately 1 nm (833 µe, µstrain) will be made. The reference FBG serves as a marker to uniquely identify a given passband of the fixed Fabry-Perot interferometer. Because of the high level of spacing uniformity, only two parameters are necessary to completely characterize the multiwavelength reference—the passband spacing and one known fixed Fabry-Perot interferometer wavelength.

System operation

The heart of the FBG interrogation system is the high-performance FFP tunable filter. Its high finesse and low mass allows high resolution and high-speed scanning. The FFP tunable filter scan ramp is generated from a 16-bit digital counter that counts (n) from 1 to 65,536 as the filter scans over one free spectral range ( 60 nm). The signal LED and the reference LED are alternately switched on and off so that the FFP tunable filter scans the multiwavelength reference and the FBGs consecutively. The reference LED is first turned on, then the fixed Fabry-Perot interferometer is scanned and the digital count corresponding to each passband is stored in a buffer with a capacity of 32 16-bit counts.

Each digital count corresponding to a zero-crossing of the reference scan is transferred to the computer during scan retrace. The known passband wavelengths of the reference compared to the count (n) of each of 22 reference passbands, can be plotted and errors detected (see Fig. 2). The shape of this error curve varies with different FFP tunable filters; however, all error curves are extremely smooth and repeatable from scan to scan allowing a relatively low order polynomial fit.

Next, the signal LED is turned on. The reference FBG and all sensing FBGs reflect wavelengths that cause digital counts to be stored in the buffer and transferred to the computer during scan retrace. Each digital count is related to a unique wavelength using the sixth-order polynomial coefficients from the previous reference scan.

Although the buffer can store values from 31 sensor FBGs and one reference FBG, the number of sensors that can be multiplexed in a practical system depends on the strain range of each sensor, the guard band between each sensor and the system bandwidth including FFP tunable filter, fixed Fabry-Perot interferometer, and LEDs. For example, if each sensor is allowed an independent strain range of � µe (1.2 pm/µe at 1550 nm) and a 200-µe guard band, then only eight sensor FBGs can be accommodated in a 40-nm spectrum.

If, on the other hand, each sensor has the same �-µe range but differs by no more than 1000 µe from adjacent FBGs, then with the same 200 µe guard band, 27 sensor FBGs can be accommodated in a 40-nm spectrum. Such high levels of multiplexing would require wavelength control during FBG manufacture in the 100-pm range. This level of wavelength control is not uncommon in FBGs manufactured for the telecommunications industry. Wavelength shifts during manufacturing operations such as mounting and laminating FBGs also would have to be accurately controlled.

Accuracy and stability measurements

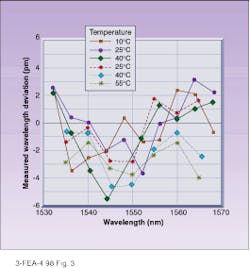

Use of a FBG interrogation system incorporating the Micron Optics multiwavelength reference has resulted in wavelength linearity improvements from a 2500-pm error to a ۬-pm curve-fitting error. Other errors due to scan repeatability, thermoelectric heater/ cooler drift, and variations due to temperature are characterized by the following technique. The output wavelength from a tunable laser source accurately measured by a wavemeter is inserted in place of the unknown FBGs allowing overall calibrated accuracy and long- and short-term thermal stability of the FBG interrogation system to be measured. Short-term wavelength accuracy of ۯ pm is achieved over the wavelength spectrum from 1530 to 1570 nm and over a 10°C to 55°C temperature range (see Fig. 3).

Micron Optics’ ferrule-based fixed Fabry-Perot interferometers are fabricated with mirrors de posited directly on the fiber etalons and containing no cement or epoxy and no air gap within the cavities. This construction results in a fixed Fabry-Perot interferometer with a long-term, stable temperature coefficient. If the thermoelectric heater/ cooler reliably holds the fixed Fabry-Perot interferometer at a constant temperature, overall system accuracy should approach the same value as shown in Fig. 3 (ۯ pm).

Combined with a 31-FBG multiplexing capacity, this technology should provide the interrogation system needed for a wide variety of mechanical sensing applications using FBGs. A slightly modified version of the FBG interrogation system could be used as a high-accuracy multiwavelength meter for telecommunication applications to sense and stabilize laser wavelength variations, provide laser failure indications within a few milliseconds for protection switching, and monitor and reconfigure multiple-wavelength networks.

REFERENCES

1. A. D. Kersey, T. A. Berkoff, and W. W. Morey, Opt. Lett. 18 (16), 370 (Aug, 15, 1993).

2. A. D. Kersey, T. A. Berkoff, and W. W. Morey, Opt. Lett. 18 (1), 72 (Jan. 1, 1993).

3. M. A. Davis et al., Proc. North American Smart Structures Meeting, SPIE 2718, 303 (Feb. 1996).

Calvin Miller is president, Tom Li is a member of the development staff, Jeff Miller is vice president of engineering and production, Faye Bao is a member of the research staff, and Kevin Hsu is director of research and development at Micron Optics, 1900 Century Drive, Ste. 200, Atlanta, GA 30345.