Laser processing of highly reflective materials is important in current manufacturing environments. However, many types of laser technology suffer from inherent sensitivity to back-reflected light, which can cause an unstable process, disruptive automatic shutdowns, or even catastrophic failure of the laser. A new generation of fiber lasers addresses these limitations with high-performance components and a novel architecture that enables uninterrupted processing of highly reflective materials (FIGURE 1).

Most multi-kilowatt fiber laser systems employ an architecture based on combining the outputs of multiple, lower-power fiber lasers using a fused-fiber combiner that could result in shortcomings in technical and economic performance. Most importantly, in the context of this article, fiber laser and combiner modules may be susceptible to instability or damage from back-reflections that occur during material processing.nLIGHT alta fiber lasers employ a novel architecture that solves these problems by housing the pump diodes and drivers in standalone pump modules, and the gain fibers in a configurable gain module that can generate >4kW of output power (FIGURE 2). The gain module incorporates a robust, integrated back-reflection isolator that protects all of the modules from back-reflections generated by the workpiece, enabling stable, uninterrupted processing of highly reflective materials. This component has been life-tested and validated in the field, where users have successfully demonstrated uninterrupted processing of reflective materials including copper, gold, silver, and highly polished metals. In discussions about these results, users state that it is the first time they have been able to process these materials without the laser turning off or experiencing permanent damage.

Back-reflection isolation

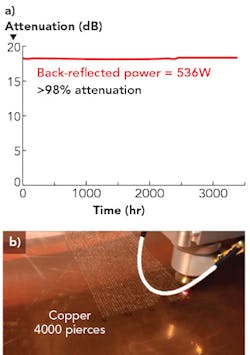

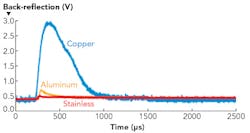

Typical back-reflections are only a fraction of the laser power because of workpiece surface irregularities, lack of precise alignment with the surface normal, and the limited collection angle of the process optics. Furthermore, the back-reflection often has a short duration; e.g., in applications such as piercing. Nonetheless, the design of some fiber lasers renders processing of reflective materials difficult or impossible. Damage caused by back-reflections usually results from deposition of optical power into polymer materials, which overheat and burn. The nLIGHT alta fiber laser strips the back-reflected light coupled into the feeding fiber and directs it to a water-cooled beam dump where it is converted to heat without any interaction with polymers, thereby eliminating the primary damage mechanism. The polymer-free isolator is designed to dump >500 W continuously, as demonstrated by a life test (FIGURE 3). We evaluated the performance of the isolation system in the case of piercing, where the highest back-reflection signals occur in laser cutting. The test successfully processed 4000 consecutive pierces of copper with no interruptions or failed pierces. In contrast to the robust, hardware-based protection provided by our back-reflection isolator, some other fiber lasers employ software protection that disables the laser in the case of a back-reflection. This approach may protect the laser, but it precludes successful continuous material processing.Highly reflective cutting results

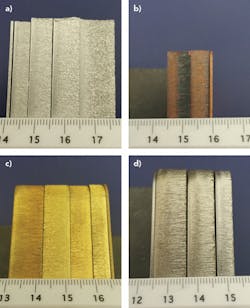

Sheet metal cutting is the largest market for kilowatt fiber lasers. Applications in the automotive, aerospace, and electronics industry, such as lightweighting and lithium-ion battery cells, are moving towards the use of highly reflective materials, including stainless steel/mirror stainless steel, aluminum, brass, copper, silver, and gold.Highly reflective welding results

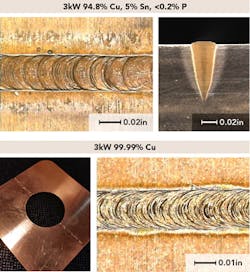

The nLIGHT alta fiber laser has also been used for welding of mild steel, stainless steel, aluminum, brass, and copper. Welding generally produces higher or more sustained back-reflections than cutting, yet no laser instability or damage has been observed, even while welding at normal incidence. FIGURE 6 shows examples of copper welding, a particularly challenging application that has caused significant damage to other fiber lasers. FIGURE 7 shows cross sections of brass welds performed with the nLIGHT alta fiber laser and with a legacy fiber laser—the superior weld quality achieved with the former is evident.The next-generation fiber laser architecture offers a revolution in kilowatt laser materials processing, particularly for reflective materials that could not be processed by previous fiber lasers because of innate limitations of their designs or in their solution to the back-reflection issue of shutting the laser off. The nLIGHT alta back-reflection isolator is fully integrated into the laser architecture.

Other solutions attempt to incorporate protection into the process fiber or in free space optics, or they use a shut-off mechanism that turns the laser off when there is risk to damage. In these approaches, the damage issue itself was not resolved, resulting in reduced uptime of the equipment and limiting the ability to process reflective materials. nLIGHT alta fiber lasers have been deployed in challenging factory environments worldwide and have demonstrated unmatched performance, reliability, and uptime in a variety of applications, including uninterrupted processing of highly reflective materials.

ACKNOWLEDGEMENT

nLIGHT alta is a trademark of nLIGHT.

REFERENCE

1 D. A. V. Kliner, "nLIGHT alta: A versatile, next-generation fiber laser platform for kW materials processing," The 84th Laser Materials Processing Conference (Jan. 19-20, 2016).

![FIGURE 2. The nLIGHT alta laser's design incorporates a back-reflection isolator between the laser and delivery fiber [1]. FIGURE 2. The nLIGHT alta laser's design incorporates a back-reflection isolator between the laser and delivery fiber [1].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2016/03/1603ils_kli_f2.png?auto=format,compress&fit=max&q=45&h=129&height=129&w=250&width=250)