Because the mid-infrared (mid-IR) spectral region coincides with the molecular fingerprint region, which is important for the spectroscopic detection and identification of many organic and inorganic molecules, the development of new mid-IR laser sources is a perennial hot topic.

One traditional type of coherent mid-IR source takes advantage of nonlinear optical frequency conversion to produce mid-IR light. Two well-known examples are the optical parametric oscillator (OPO) and its sister, the optical parametric amplifier (OPA). However, these sources, which use a nonlinear optical crystal to convert a shorter-wavelength laser input beam to a coherent mid-IR beam, are complicated, inefficient, and expensive.

The development of the quantum-cascade laser (QCL) and interband-cascade laser (ICL) has resulted in small and rugged commercially available mid-IR sources that serve well for low-power and energy applications, but fall short when more output is needed.

Another contender for a mid-IR laser-gain material is transition-metal (TM) doped II-VI semiconductors such as iron-doped zinc sulfide and zinc selenide (Fe:ZnS and Fe:ZnSe) and chromium-doped ZnS and ZnSe. In fact, these materials can be used in fiber lasers with output powers of up to 20 W.

Another mid-IR laser of this type is based on tellurides, using iron as the dopant and either cadmium or zinc telluride as the base (Fe:CdTe and Fe:ZnTe). These materials produce longer wavelengths than Fe:ZnS and Fe:ZnSe and thus expand the wavelength range reachable by such lasers. However, these telluride materials have been difficult to produce.

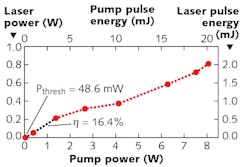

A group of researchers from the Air Force Research Laboratory (Wright-Patterson Air Force Base, OH), Berrie-Hill Research Corporation (Dayton, OH), and NAS/NRC Research Associates Programs (Washington, DC) has now produced working laser crystals of Fe:CdMnTe (which is similar to Fe:CdTe, but contains some manganese).1 The output wavelength of the first prototype was 5.223 μm and had an 810 mW output power, and demonstrated a slope efficiency of 16.4%.

Material characterization

The researchers had Brimrose (Sparks Glencoe, MD) grow a boule of Fe:CdMnTe from melt using the so-called Bridgman technique, which produces directional solidification of the melt by moving it gradually from a hotter to a cooler portion of the furnace. The Fe:CdxMn1-xTe material had an alloy fraction x of 0.91, as determined by refractive-index measurements.

The absorption of the fabricated sample was mapped using a Fourier-transform interferometer (FTIR), and the sample was then diced into rectangular pieces. One of the pieces was cryogenically cooled and its transmission spectrum measured via FTIR. In addition, the mid-IR fluorescence of the piece was characterized by exciting it with laser pulses at a 3.45 μm wavelength from an OPO.

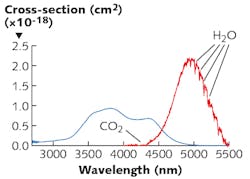

The fluorescence lifetime was determined by fitting an exponential curve to the measurements-it was found to be 111 μs at 80 K and 78.5 μs at 10 K. The fluorescence spectrum was measured using a spectrometer by Princeton Instruments (Trenton, NJ). From this information, the emission cross-section was calculated (see Fig. 1).

Laser prototype

The slab-shaped experimental sample of Fe:CdMnTe measured 2.65 × 4 × 7 mm, and was polished and antireflection-coated for a 4.5–5.5 μm wavelength band on the 2.65 × 7 mm sides. The sample was mounted to a copper cold finger and placed into a mostly evacuated (1 mTorr) dewar, where it was cooled to 77 K with liquid nitrogen.

The x-cavity laser configuration included three mirrors with >98% transmission at the 4 μm pump-laser wavelength and high reflection in the 4.5–5.5 μm wavelength band. The cavity output mirror had a 65% reflection at 5.2 μm. While the optimum beam waist within the cavity was calculated to be 95 μm, the actual beam waist was measured to be about 190 μm—a large difference. As a result, this first experimental prototype was not expected to be operating near the highest possible efficiency. The pump laser, a Fe:ZnSe fiber laser made by IPG Photonics (Oxford, MA), emitted 220 μs pulses at a 400 Hz repetition rate.

The output spectrum of the Fe:CdMnTe was measured with a mid-IR spectrum analyzer (OSA) made by Thorlabs (Newton, NJ), showing the laser's 5.223 μm center wavelength and a 1 nm spectral width. The researchers were surprised at the narrowness of the laser's bandwidth, as ternary crystals such as Fe:CdMnTe usually have more defects than do binary crystals such as Fe:ZnS and so on, and thus normally show some broadening. The researchers attribute the narrow linewidth to the uniformity of doping achieved by the Bridgman crystal-growth technique.The output power, measured after the laser's output coupler, was determined to be 810 mW for 8.05 W of input pump power (see Fig. 2)—a total efficiency of 10.1%. The researchers next plan to optimize the laser-cavity setup and to create a higher vacuum so that the laser light is less absorbed by remaining air. Replacing one of the laser-cavity mirrors with a blazed grating in the Littrow configuration should allow wavelength tuning from 4.6 to 5.4 μm.

REFERENCE

1. J. W. Evans et al., Opt. Mater. Express (2017); https://doi.org/10.1364/ome.7.000860.