In optical design, aberrations occur when light from one point of an object doesn’t converge into or diverge from a single point after transmission through the system. The non-linear terms in Snell’s Law cause deviations from perfect imagery: optical systems that form images will produce images that aren’t as sharp. Optical engineers must correct the aberrations to produce the sharpest images possible.

Six common types of optical aberrations

- Defocus: The optical system is out of focus, reducing the sharpness of images produced by the system.

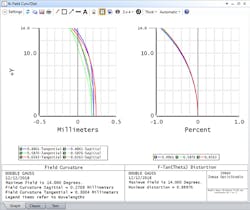

- Radial distortion: Images with radial distortion usually have symmetric distortion due to the symmetry of a lens. There are three types of radial distortion: barrel, in which image magnification decreases with distance from the optical axis; pincushion distortion, in which image magnification increases with distance from the optical axis; and mustache distortion, which is a blend of the two types. Chromatic aberration is radial distortion that depends on wavelength.

- Astigmatism: Rays that propagate in two perpendicular planes have different foci. Where the horizontal and vertical axes cross, the axes will be in sharp focus at two different distances. There are two forms of astigmatism: third-order aberration, which occurs for objects away from the optical access; and when the optical system is not symmetric about the optic axis.

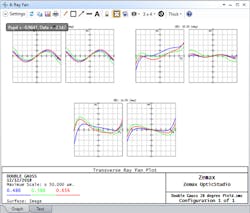

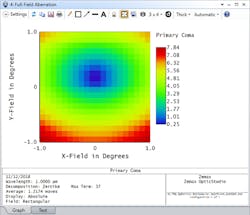

- Coma: Defined as a variation in magnification over the entrance pupil, coma is seen often in telescope design, resulting in stars or other objects appearing to have a tail.

- Spherical aberration: This occurs when there is increased refraction of light rays striking a lens or when there is a reflection of light rays striking a mirror near the edge versus closer to the center.

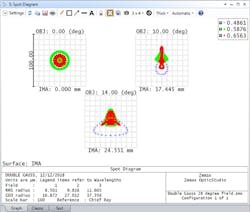

- Petzval field curvature: Named after physicist Joseph Petzval, one of the founders of geometrical optics, this is an aberration in which a flat object cannot be brought into focus on a flat image plane.

Solving optical aberrations with optical design software

Many optical aberrations can be easily solved with the right optical design software. For example, OpticStudio from Zemax, the industry-leading optical design software, has many features and functionalities that help correct common aberrations.

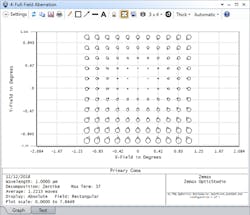

For example, OpticStudio offers the Full-field Aberration Analysis feature, which allows optical engineers to improve freeform designs by analyzing how various aberrations degrade the image or beam quality of a system across the full field of view. Freeform optical surfaces are a key element in many modern optical systems, used for example in virtual and augmented reality designs. This analysis feature displays aberrations and contributions to image degradation across the full XY field of view. Users can analyze freeform systems, in the same way they would with any other regular sequential system, identifying the change in aberrations across the field of view and getting an indication of how to correct these.

eGuide: How to understand how contrast varies or is lost in an optical system

Understanding contrast loss in an optical system is as important as correcting for aberrations. Learn the basics.